Preventing Damaged Grain With Probe-A-Vac®

An air-powered vacuum provides customers with more efficient methods for sampling and maintaining the quality of stored grain.

January 01, 2015

Following the harvest season, farmers stockpile their bounties of grain in large storage bins. This keeps the grain cool and sweet throughout the winter, and ready for processing come spring. Sometimes, due to hatches of insects, mold growth, trapped heat and other harmful influences, damaging “hot spots” can form within the bins of stored grain, compromising the crop’s quality and decreasing market value.

Historically, grain operators had to address hot spots by hand, sifting through the bin—and sometimes completely emptying it—to find the problematic areas. It was a devastating task for farmers, especially as spring approached, since it added more heat to the grain and often ruined portions of it.

Cargill’s grain business, founded in 1865, managed the issue of hot spots for nearly a century. But in 1961, the company’s grain research laboratory addressed the problem with a major breakthrough. The team developed the Probe-A-Vac® grain sampler, a probe that used a vacuum to sample stored grain and identify hot spots with twice the speed and accuracy of old methods. With the new technology, storage operators could locate trouble areas as deep as 100 feet without emptying the bin and damaging the crop. For infestations, the pointed nozzle of the probe could inject insecticide directly into the hot spot, eliminating insects with no effects on the rest of the grain.

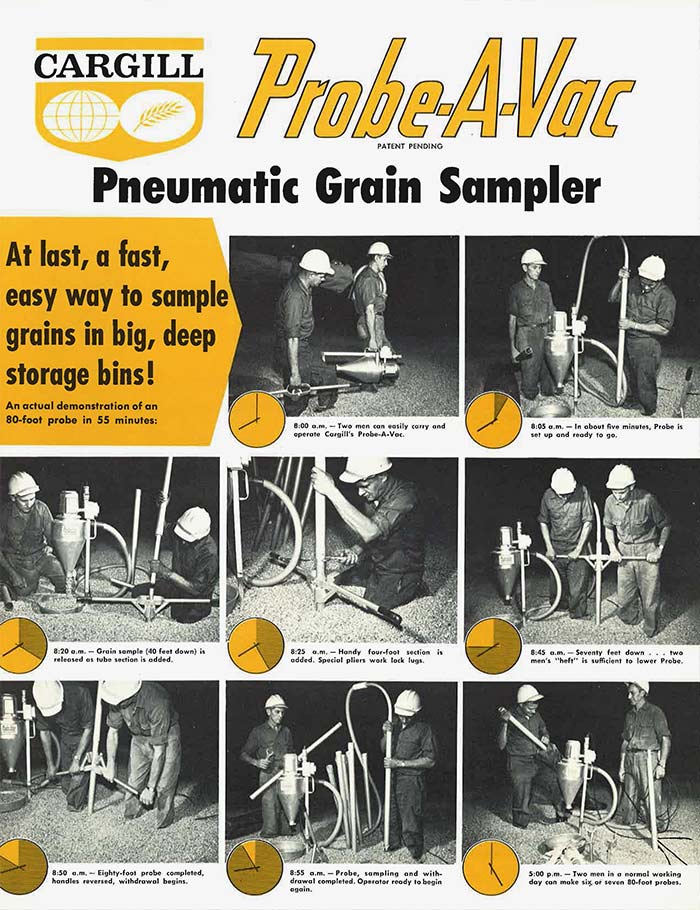

[image caption] An instructional pamphlet from Cargill shows how farmers use the probe to take several samples of grain from a storage bin—as deep as 100 feet—in just one hour.

[image caption] An instructional pamphlet from Cargill shows how farmers use the probe to take several samples of grain from a storage bin—as deep as 100 feet—in just one hour.

Two years after the successful debut of the Probe-A-Vac system, Cargill modified the unit to enhance another industry: cottonseed. Using a series of interlocking sections of aluminum tubing, the revised probe penetrated piles of cottonseed up to nine times deeper, using only half the manpower. Though Cargill sold the Probe-A-Vac name and invention to Tandem Products, Inc., in 1987, the design endures as an industry benchmark, still used by farming customers everywhere.