Xanthan Gum

Cargill's xanthan gum range is extensive. It includes regular and transparent grades, available in powdered or granulated form.

Cargill's xanthan gum range is extensive. It includes regular and transparent grades, available in powdered or granulated form.

Applications

Xanthan gum is known for its thickening and stabilizing properties. Thanks to its unique rheological properties, xanthan gum is commonly used in many food and specialty industrial applications. These include:

- Baking applications and pastry, e.g. bread, cake

- Beverages

- Dairy applications

- Dressings and sauces (emulsified sauces, tomato-based sauces, sauces with particles in suspension, dry mix sauces)

- Fillings

- Frozen desserts

- Fruit applications

- Meat applications

- Non-food applications, e.g. household products, cleaners, agricultural, paints & coatings, oral care, personal care and pharmaceuticals

- Powder products

- Syrups

- Toppings

Brands

Cargill's xanthan gum products are available under the following trademarks:

- Satiaxane™ (Xanthan gum) - Food, cosmetic and pharmaceutical

- Verxan™ (Xanthan gum) - Non-food

Certification System

Cargill xanthan gum produced in Europe and China is Kosher and Halal certified. All regional, national and international certifications are issued by well-known official certification bodies and available upon request.

Depth of Expertise

Cargill offers a wide and unique range of biopolymers. As part of its mission to look after the needs of its customers anywhere in the world, Cargill can adapt formulations and production specifications to particular requirements such as national, religious, legal and safety constraints.

Over the years Cargill has acquired thorough knowledge of all relevant technologies for producing xanthan gum. Its expertise is based on the knowledge of both the specific requirements of a broad spectrum of industries and the characteristic properties of xanthan gum. This results in special products optimized for specific applications.

Functionality

Xanthan gum is a biopolymer.

Xanthan gum is produced as a secondary metabolite by a fermentation process, based on the culture, in aerobic conditions, of the micro-organism Xanthomonas campestris.

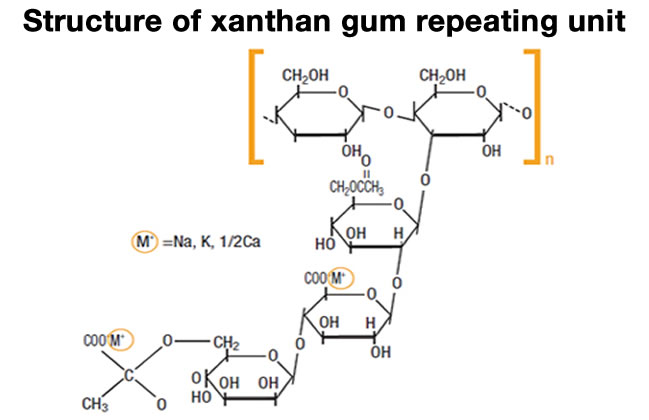

Xanthan gum is a hetero-polysaccharide with a very high molecular weight (between one and several million). Its main chain is composed of glucose units.

The side chain is a trisaccharide, consisting of alpha-D-mannose that contains an acetyl group, beta-D-glucuronic acid, and a terminal beta-D-mannose unit linked with a pyruvate group.

The monosaccharides present in xanthan gum are: beta-D-glucose, alpha-D-mannose and alpha-D-glucoronic acid in a ratio of 2:2:1.

The beta-D-glucoses are (1->4) linked to form the backbone. Alternate glucoses have a short, three-sugar branch consisting of a glucuronic acid sandwiched between two mannose units. Thus, the overall repeating structure is the pentasaccharide.

The terminal mannose can have a pyruvate group attached and the mannose adjacent to the main chain may have an acetyl group attached to C6. In general, about one branch in two has a pyruvate group, but the ratio of pyruvate to acetate varies depending on the substrain ofXanthomonas campestris used and the conditions of fermentation. The glucuronic and pyruvic acid groups give xanthan gum a highly negative charge. These acid groups are neutralized using sodium, potassium or calcium ions for food products.

In their solid state xanthan gum molecules have a helical structure. The branches fold in, to lie along the backbone.

Xanthan gum is a thickening agent. Its rigid helical structure can be melted, leading to a disorganized state with lower viscosity. The organized state is stabilized by the presence of electrolytes. The transition temperature is above 100° C in the presence of small quantities of salt.

The presence of anionic side chains on the xanthan gum molecules enhances hydration and makes xanthan gum soluble in cold water.

Xanthan gum is one of the most successful hydrocolloids due to its unique functionality, particularly in difficult environments like acid, high salt and high shear stress.

Temperature and acid stability

Solutions of xanthan gum are generally not affected by changes in pH value. Xanthan gum will dissolve in most acids or bases.

Viscosity control

The viscosity of xanthan gum is stable at low pH values and at high temperatures for a long period of time.

Salt tolerance

Viscosity is not affected by the addition of large amounts of salt; for example, in a 250 liter sodium chloride brine, only a slight increase in viscosity can be observed.

Freeze/thaw stability

Thanks to its water binding capacity, xanthan gum solutions exhibit good freeze/thaw stability.

Compatibilities

Xanthan gum is cold soluble, providing high viscosity and pseudoplastic behavior at low concentration. It can be directly dispersed in oil or a sugar solution to avoid introduction of air bubbles in water or when water is not directly available in the formulation. Dissolution takes place during processing. In order to facilitate handling, dust-free and granulated versions assist dispersion or dissolution needs.

Xanthan gum has a synergistic effect in combination with locust bean gum and konjac (gel formation) as well as with guar gum (higher viscosity). Thanks to the unique rheological and synergistic properties of its aqueous solutions, xanthan gum is used in many applications as a suspending agent and emulsion stabilizer, a foam enhancer or an improver of dough volume.

Manufacturing

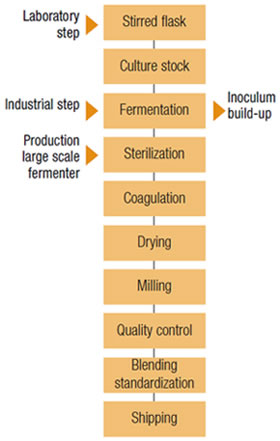

The strain is preserved in a freeze-dried state. It is activated by inoculation into a nutrient medium containing a carbohydrate, a nitrogen source and mineral salts. After growth, the cultures are used to inoculate successive fermenters right through to the industrial scale.

Throughout the fermentation process, pH, aeration, temperature and agitation are monitored and controlled.

Once the carbohydrate is exhausted, the broth is sterilized. Then, the fermenter is emptied, cleaned and sterilized before the next fermentation takes place.

Xanthan gum is recovered by precipitation in alcohol (isopropyl or ethanol). The coagulum obtained is separated, rinsed, pressed, dried and ground before quality control.

Partners in Success

In Cargill’s xanthan gum business, we take the time to understand your specific needs in order to provide solutions, not just products. Worldwide customers recognize this and benefit from our:

- Modern plant production facilities using the latest fermentation, separation and drying technologies

- Wide range of xanthan gums for food applications, including standard, dust-free, granulated and transparent

- Cost-effective range for industrial applications including standard, dispersible and clear xanthan gums

Helping your business succeed by differentiating you from your competitors is our primary goal.

Production Site

Cargill produces xanthan gum in the following plant:

- Baupte (Normandy), France - ISO 9001: 2000

A producer of biopolymers since 1983, Cargill has extensive knowledge ranging from raw materials through to finished products.

Each production batch is produced under controlled conditions to ensure consistency of performance in application in compliance with Cargill's ISO certifications.

All xanthan gum produced at Cargill is manufactured with the highest degree of safety and environmental stewardship.

Regulatory Status

FAO/WHO - Codex Alimentarius

Xanthan gum has been given an Acceptable Daily Intake (ADI) of "not specified" by the FAO/WHO Joint Expert Committee on Food Additives (JECFA).

European Union

Xanthan gum (E 415) is listed in Annex I of the European Parliament and Council Directive 95/2/EC of 20th February 1995 on food additives, and may be used at “quantum satis” in many food categories.

United States

The FDA recognizes xanthan gum as permitted for direct addition to food for human consumption in the Code of Federal Regulations (CFR 21, § 172.695).

Cargill's global team of regulatory and food law experts will be glad to provide assistance on regulatory, nutrition-related claims and food law-related issues.

Some Cargill products are only approved for use in certain geographies, end uses, and/or at certain usage levels. It is the customer's responsibility to determine, for a particular geography, that (i) the Cargill product, its use and usage levels, (ii) the customer's product and its use, and (iii) any claims made about the customer's product, all comply with applicable laws and regulations.