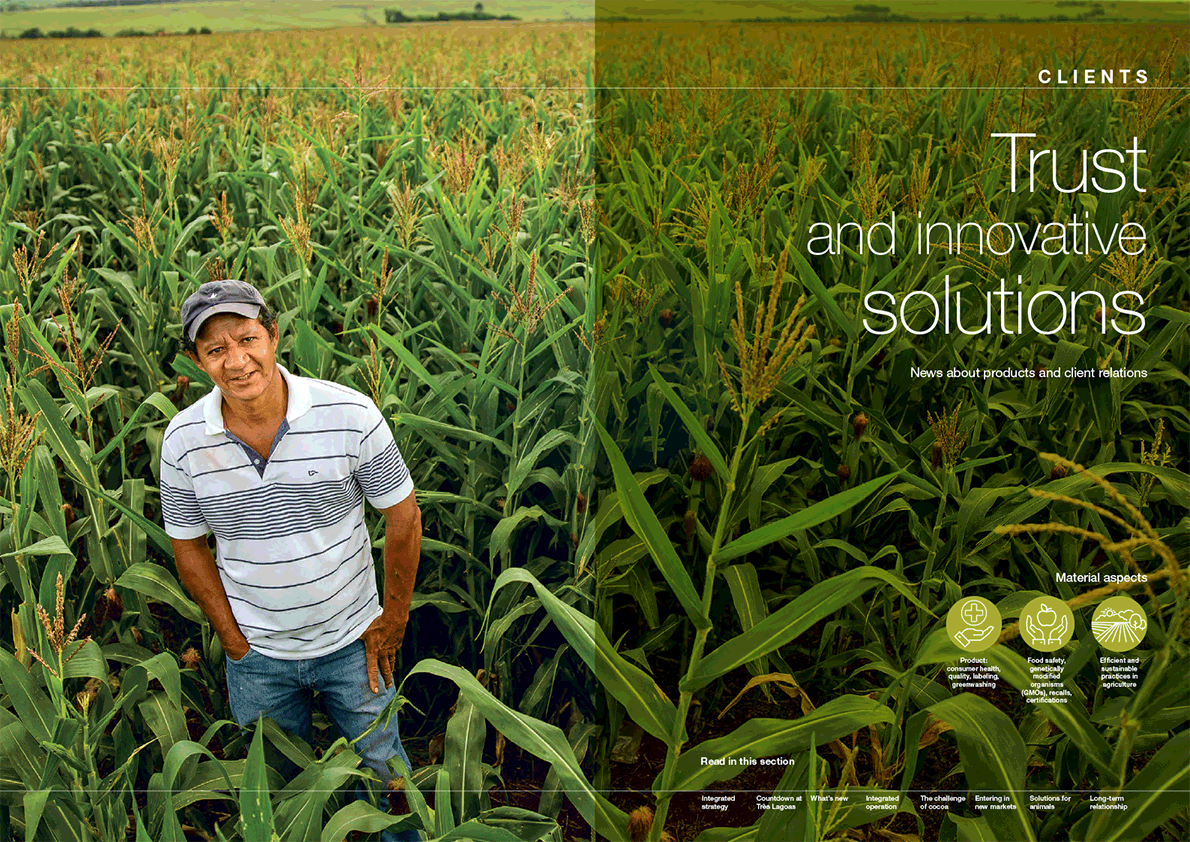

Cargill and its clients

In order to feed the world safely, responsibly, and sustainably, Cargill has a growing need to strengthen bonds of trust with clients, who take our products to end consumers. The success of the company depends on the ability to offer them efficiency and solutions aligned with the best economic, social, and environmental practices. We want to be our clients' first choice.

Bond of trust

In this section, we present the main challenges, lessons learned, and developments in initiatives such as:

Integration of our grain-related business and soybean processing in South America

Expansion of Três Lagoas (MS)

Partnership with the Spanish brand Borges

Consolidation in the cosmetics sector - with the development of new technology

Beginning of the operations of one of our clients on the site of our corn biorefinery, in Castro (PR)

Impact on cocoa production, caused by the drought in Brazil and other factors

Continuous efforts to improve our production process, using the Elefante brand as an example

Cargill Business Service (CBS) progress

See these and other aspects below.

3,200

tons/day is the soybean processing capacity in Três Lagoas after expansion.

Integrated strategy

The management style of grouping similar businesses in the same business platform reached South America. In 2016, we began to operate in an integrated fashion throughout the grain production chain and processing of soy, cotton, sugar cane, corn, palm, sorghum, and wheat from Argentina, Bolivia, Brazil, Colombia, Ecuador, the United States, Paraguay, Peru, the Dominican Republic, Uruguay, and Venezuela.

The main objective of the new business management model is to leverage synergies and gains in efficiency, which the company intends to translate into performance benefits for shareholders, clients, suppliers, employees, and the communities where we operate.

Benefits:

Agility

Quality of products and services;

Competitiveness

More operational safety

Career opportunities for employees

Countdown at Três Lagoas

We began the first operational tests and are almost ready to reopen our soybean milling plant in Três Lagoas (MS), whose expansion work began in 2014. With an investment of BRL 240 million, the soybean processing capacity jumped from 2,100 tons/ day to 3,200 tons/day beginning in 2017, when we resumed 100% of the operation, which will allow us to increase the production of meal and oil for producing biodiesel.

In biodiesel production, glycerin is also obtained, used in several industrial applications. With the refinery, a 99% pure glycerin will be produced, whose applications are directed to the cosmetics, food, and beverage industries.

The expansion project also includes the expansion of rail and waterway modes, through which we will transport our production. The extension of the rail terminal will serve to improve the biodiesel load; and the waterway terminal will improve for the meal load.

What's new

With experience in distribution and the strength of the brands Borges and Maria, Cargill is preparing to market the products domestically. See also the highlights of 2016 in the categories of tomato sauces and oils and fats.

Promising partnership

The agreement to market products from Borges Branded Foods was one of Cargill's main initiatives in the food category in 2016. Since September, we added extra virgin olive oil, the premium olive oil line, and Borges balsamic vinegar to our portfolio, as well as the new Maria extra virgin olive oil, directly from Spain.

In the last months of the year, we were dedicated to importing and analyzing the product line and distribution strategies. We combine Borges' knowledge and tradition with Cargill's excellence in execution. We want to cover national territory - remembering that Borges is already very strong where it is present, mainly in the Southeast Brazil. Communications actions are planned for the second half of 2017.

Successful series

In Pomarola, leader in its category, we continued the Pomarola Chef line with the launch, in September 2016, of Provençal sauce signed by French chef Erick Jacquin. The series began during the previous year with a recipe of tomato sauce with lemon, olive oil, and basil developed by Carla Pernambuco. The brand, characterized by innovation and pioneering, has the right conditions for our company to establish partnerships with renowned chefs.

In the Elefante Saborizado line, we put two more flavors on the shelves, stroganoff and marinade, which now make up the series alongside bay leaf, fine herbs, and onion and garlic. The new products are the result of extensive research, in which we identified that the consumers of the brand expect quality associated with practicality in their daily lives, with flavors already known by their palate.

Contribution to the market

In order to demonstrate our commitment to Brazil's current standards, we comply with the National Health Surveillance Agency (ANVISA), and in August 2016, we started a public campaign to collect products from the consumer market. We point out that Cargill adopts strict controls of food safety, hygiene, and quality, as well as best manufacturing practices, as established in the applicable standards, in order to guarantee a product that does not pose any health risk. We evaluate health and safety impacts and look for improvements in almost 100% of our significant product and service categories. (G4-PR1)

Regardless of the collection issue, it should be noted that in the last five years we have made solid investments in processes and equipment throughout our production chain, which involves activities in the field, harvesting, separating fruit, transport, and cleaning, reinforcing Cargill's conviction to continuously improve itself through technologies and innovating processes and products.

Adequate labels

Strong culture and consistent policies reflect Cargill's commitment to food safety. Therefore, we contribute, alongside representative associations of the food industry, to ANVISA's new regulation requiring information on allergenic foods on the labels.

Within the company, we trained our employees involved in this issue to ensure that information was available and clear on our labels and the specifications for the production market, as soon as the resolution was published on July 3, 2016.

We are strongly committed to food safety.

More sustainable packaging

In order to complete the Elefante brand packaging portfolio, we have the tetrapack concept available throughout Brazil. It is also worth noting that in 2016 we began implementing a series of initiatives to make our packaging more sustainable, with the maximum possible reduction in the use of raw materials in its production, such as layers of aluminum, paints, and paper.

Homemade flavor

In the Liza line, the main advance in 2016 was in mayonnaise - we bet on a differentiated product: Liza Caseira with extra virgin olive oil. The purpose is to make the traditional recipes for mayonnaise tastier and more full-bodied, with touch of olive oil to provide more flavor.

Oil that yields more

Cargill has been increasingly active in the foodservice market, with new solutions and by expanding its portfolio. In oils and fats, we already had an extensive range of products, more focused on the big operators. In 2016, we launched Liza Algodão, a special oil for frying, focusing on small and medium operators.

Integrated operation

Our corn biorefinery, in Castro (PR), already operates with the first client based at our site. With this model, unprecedented for this segment in Latin America, we expect to have social and environmental gains, and boost business in the region and long-term business relationships.

In a market with a growing demand for a higher value-added product that overcomes the commodity concept, Cargill has been investing in its portfolio in the area of starches and sweeteners, constant labor training, and structuring differentiated services. In March 2016, we consolidated an important part of this strategy: serving clients with factories on the same site.

The project began three years ago, with the inauguration of the Castro plant, located 200 kilometers from Curitiba (PR), where we process corn for the production of its by-product ingredients, such as starches, glucose syrup, and dextrose. With this initiative, we created about 800 indirect jobs in the region. The total area is 352 hectares, of which 2.5 are occupied by Cargill. The rest is occupied by other partner company facilities. Our first neighbor is Evonik, a world leader in specialty chemicals.

WHAT WE DO

We pipe dextrose directly to the Evonik factory, which processes it into amino acids.

We serve the national market with solutions in starches and sweeteners for use in dairy products, candies, confectioneries, beverages, breads, and in the paper and cardboard industry, as well as animal nutrition.

OUR STRATEGY

To install factories in regions with availability of raw material, adequate logistics conditions, and infrastructure.

Be close to clients

Offer differentiated service.

WHAT WE WANT

Long-term business relationship

To boost business in the region

The challenge of cocoa

To mitigate impacts caused by Brazil's drought and economic downturn, and fulfill our 2016 commitments, we seek even more efficiency by importing part of the raw material needed in our cocoa and chocolate operations.

The year 2016 can be summarized as a challenging year for the cocoa business, for Cargill and the whole country. Three main factors made the scenario more difficult in the period:

The severe drought in Bahia was detrimental to the crop, and also demanded efforts in water management

The low availability of raw materials affected our price competitiveness

There was a drop in Brazilian purchasing power, who in the last three years began replacing products with higher value added with cheaper options

It is important to point out that Brazil has a more complex reality regarding cocoa than the rest of the world. We are the only country with great consumption potential that produces cocoa itself.

In this context, two areas support our work regarding the development of this market. We are dedicated to both productivity, with significant investments in partnership programs, and adequate environmental and social conditions for cocoa production. For these reasons, in addition to launching a certified product, today Cargill is one of the leaders in this discussion and in the quest to improve sustainability in the Brazilian cocoa crop (see “Sustainability in the cocoa supply chain”).

Certified Chocolate

The Genuine line, produced by the company for the foodservice segment, already has Genuine UTZ Milk Chocolate, made from certified cocoa beans. The UTZ seal guarantees that the best practices of management, cultivation, and safety have been adopted throughout the cocoa production chain, from the farms in Bahia to the factory where chocolate is produced, in Porto Ferreira (SP). The product is offered in 1.05 kg bars and can be used for making Easter eggs, truffles, toppings, fillings, and desserts, among other culinary recipes. Cargill's desire is for other companies to embrace this trend by increasing the volume of certified chocolates and byproducts, thus benefiting the entire chain and Brazil (see “Sustainability in the cocoa supply chain”).

Entering in new markets

With the challenge of doubling its market share over the next three years, Cargill begins operating throughout the industrial oil production chain and enters the cosmetics market.

For the Cargill Industrial Specialties (CIS) business unit, focused on the production of high value added industrial oils - 100% renewable and biodegradable -, the year 2016 was a significant evolution. We gained new clients, entered the cosmetics segment by launching Lyveum (see table), an unprecedented solution for the cosmetics market, and acquired a micro-ingredient company in Ponta Grossa (PR).

Some factors contributed to CIS dealing well with obstacles such as the country's political and economic recession and difficulties in the processing segment, also affected by the price of oil. Some of the main ones are:

Portfólio Diversity - We operate in the consumer, personal care, processing, oleo chemical, and corp protection segments, a variety that allows us to better overcome periods of crisis;

Technical competence in providing services and controlling costs.

New factory

WHAT WE DO

The new factory, based in Ponta Grossa (PR), processes and produces oleo chemicals and emulsifiers for the food, animal nutrition, and industrial segments in the domestic market and for export.

NEW STRATEGY

The acquisition of the plant is an essential part of Cargill's long-term vision.

We are widely recognized as a food industry in the country and we want to become stronger in the industrial area as well.

WHAT WE WANT

Increase the production capacity of CIS, since the Mairinque (São Paulo) plant is at its production limit.

Increase the product portfólio.

Act throughout the production chain of industrial oils.

Ultraóleo, pioneering solution

Increasing the validity of the final product and reducing the level of oxidation were some of the technical issues that Cargill scientists overcame in order to achieve an ultra-refined vegetable oil much desired by cosmetic manufacturers. Lyveum oil expands our portfolio of biodegradable products and gives the final product the same properties and stability of a mineral oil (petroleum by-products). Pioneering the application in cosmetics, the technology is being patented and is already being marketed by Cargill.

Solutions for animals

The drop in Brazilian purchasing power and the historic rise in the price of corn in 2016, due to water instability that resulted in a 20% reduction of the country's corn crop, also required extra efforts from the animal nutrition segment, which includes our Animal Nutrition business. With the economic recession, people began consuming less animal protein, since it is more expensive than vegetable protein, affecting the financial structure of the whole chain.

The challenges, however, did not stop us from moving forward in our purpose of becoming a key partner. To address these challenges, we rely on our business model and intensify our efforts to bring new products, new technologies, and qualified service to producers and ranchers, to help them through this most critical period, contribute to their growth, and strengthen our business ties.

With three factories, located in Itapira (SP), Toledo (PR), and Chapecó (SC), the Animal Nutrition business in Brazil has an annual revenue of BRL 700 million - and the advantage of having the experience and cutting-edge solutions developed by our global matrix. We stand out on four major fronts of animal nutrition in the country - pig farming, dairy cattle, beef cattle, and poultry - and we provide, on a much smaller scale, nutrition for domestic animals such as dogs and cats.

Learn about some of our differentiators, and what we offered to the market in 2016:

Differentiators

GLOBAL KNOW-HOW, LOCAL PRESENCE

We have solutions from two global Cargill Animal Nutrition research centers. A third team in Brazil develops specific applications, products, and technology for our production, climate, and soil characteristics.

EXCELLENCE IN SERVICE

We provide technical support to our clients through the specialized work of 150 employees, trained in veterinary, animal science, and agronomy.

SUSTAINABILITY

We work with national suppliers selected and registered in our system, which periodically evaluates the conduct of companies on issues such as bonded labor and illegal deforestation.

Highlights of the year

PIG FARMING

Launch of the Rapid TPS feed (technology, convenience, and safety), directed to piglets in the post-weaning phase. It is designed to be a highly nutritional, practical, and sustainable food, which allows for reduced manufacturing costs, energy savings, and lower storage of ingredients. We want to improve the zootechnical and financial results of this phase of breeding, positively impacting the other stages of animal husbandry. To develop it, we invested USD 1.5 million in the implementation of a production line at our factory in Toledo (PR).

DAIRY CATTLE

An odorless powder added to the cow's feed helps to balance the animal's temperature so that it continues to have an adequate appetite, and as a result, it continues to produce good amounts of milk. The solution helps maintain proper body temperature and was developed by global Cargill especially for tropical countries, in other words, in very hot regions.

POULTRY

In poultry, we highlight our food additives, which act on the digestive system, benefiting the intestinal microflora and, with this, the growth of the birds. The solution replaces antibiotics in the production of this type of meat, increasingly consumed by the population.

BEEF CATTLE

In 2016, we launched our line of minerals and entered this market in Brazil. With this, we want to strengthen our position in production for pasture, a business in which the country, due to its territorial characteristics, is well developed. At Cargill's entrance into this segment, we are investing USD 7 million in the production of minerals in Itapira (SP).

PETS

A new line of premium foods for dogs and cats brings the advantage of containing meat in its formula, increasing the absorption of nutrients and making it better accepted by the animals. The product contains no dyes and helps to control urinary pH, among other benefits. It is the result of the partnership between different areas within Cargill, from research to marketing, in an increasingly frequent practice in our operations in Brazil and worldwide.

Long-term relationship

Banco Cargill is the financial arm of Cargill in Brasil. This way, we are always close to producers. We closely understand their reality and their needs, and work to achieve a virtuous cycle, in a safe, healthy financial scenario guided by ethics and best market practices.

The institution provides services and loans to agricultural, industrial, and cooperative clients through an agile credit approval process, won by Cargill's credibility and knowledge of agribusiness. In 2016, we went through a phase of severe instabilities in patterns of rainfall, aggravated by the loss of the country's investment grade at the end of 2015. The States of Maranhão, Tocantins, Piauí, and Bahia had a 50% crop failure in cotton and 40% in soybeans. In Goiás, there was a 75% crop failure in corn. In Bahia, which experienced its fourth year of drought, we also faced the problem of helicoverpa, one of the most aggressive pests in agriculture.

Given this scenario, our strategy was to stay with rural producers, providing financial alternatives in a time of severe shortage of financing in the market. We plant long-lasting relationships and are confident about the 2017 crop, which looks as if it will yield good results.

Bank figures in 2016

BRL 4,295,862

in assets

4%

higher than the previous fiscal year.

The loan portfolio showed a small drop of 3%, reaching BRL 2,798,051.

Loss of BRL 3,097, caused mainly by the provision for doubtful accounts due to the adverse economic scenario. These credits were successfully renegotiated, and clients are constantly monitored by the Bank's Credit and Risk and Commercial areas.