Case Study: NCAT Test Track

Situation

In the road construction industry, there tends to be a lack of comprehensive performance studies being conducted on rejuvenated highly recycled HMA. Without such valuable research, many across the industry don’t have the credible information necessary to understand the role rejuvenators have in the asphalt construction space and the value it brings.

July 07, 2021

Goal

The team established this multi-year test to help answer critical questions surrounding how performance-based specifications can be used by agencies to allow and specify rejuvenated high-RAP mixes, while also demonstrating the viability, longevity and overall performance of High-RAP mixes using Cargill’s Anova® Rejuvenator. The test, now beyond the initial three-year period, and scheduled to be extended an additional three years, is well positioned to serve as a national reference on rejuvenation tests and benchmarking for the industry.

The findings, shared freely with state agencies and businesses throughout the industry, will allow for more informed decision making when it comes to alternative pavement designs and performance-based specifications.

In addition to the test with NCAT, Cargill has also completed a two and half-year evaluation of rejuvenated mix in cold weather climates at Minnesota Department of Transportation’s MnROAD test track on a major interstate section just outside the Twin Cities metro area.

Solution

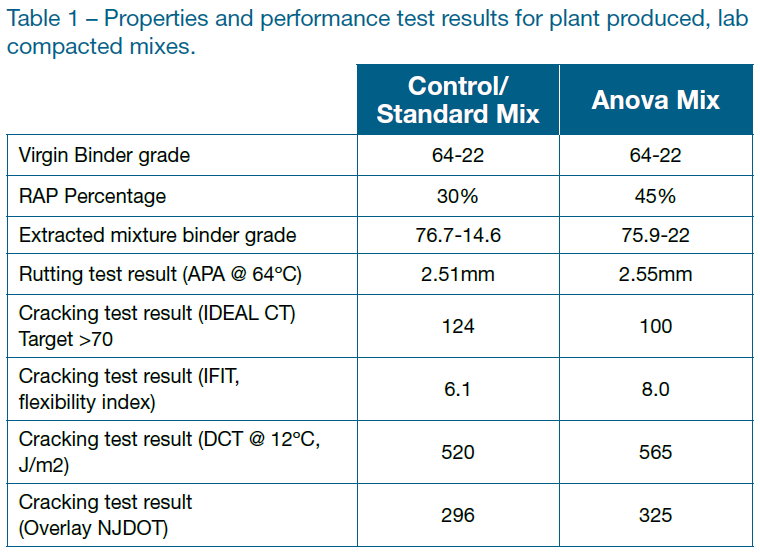

The team designed a comprehensive, research program assessing actual in-the-field pavement performance with a 45% RAP mix against a control mix at 30% RAP (9.5mm NMAS VDOT BMD mix).

At the lab scale, the team has been analyzing plant produced mix from the test track at various conditions in terms of cracking, rutting, moisture resistance,and other properties at the NCAT testing facility in Alabama.

According to Dr. Buzz Powell, Associate Director and Research Professor at NCAT, this type of testing is critical in advancing innovations in the road construction industry.

“Hats off to Cargill for funding such important research with results shared with 34 state agencies in the country,” said Powell. “This work adds so much credibility to the use of RAP and helps the entire industry move forward with proven technologies that brings greater value to our communities and road construction businesses as a whole.”

Results

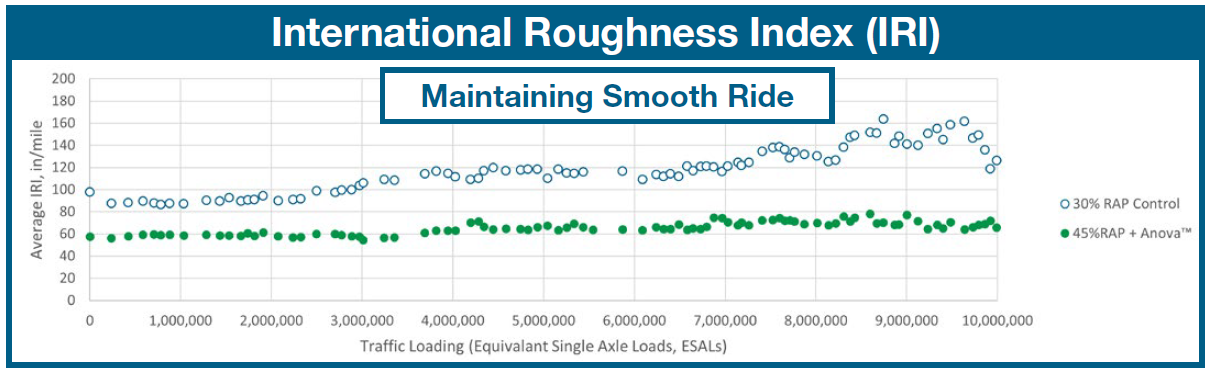

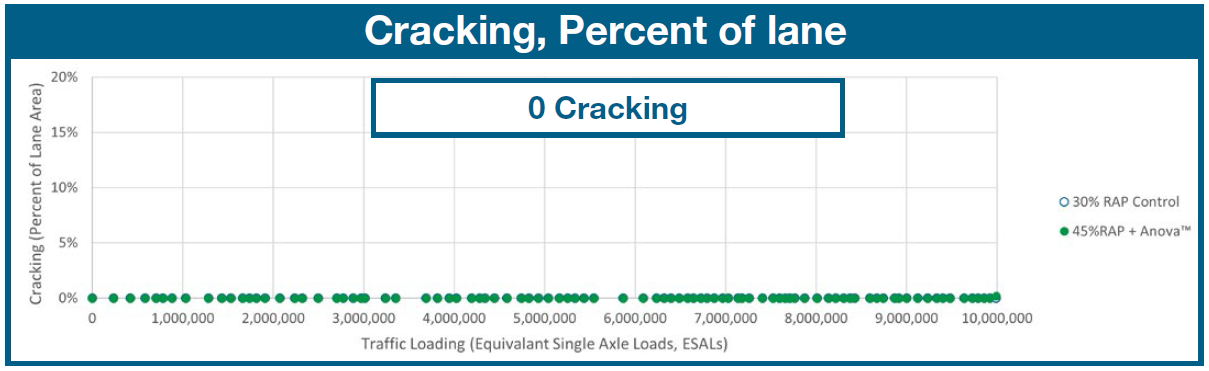

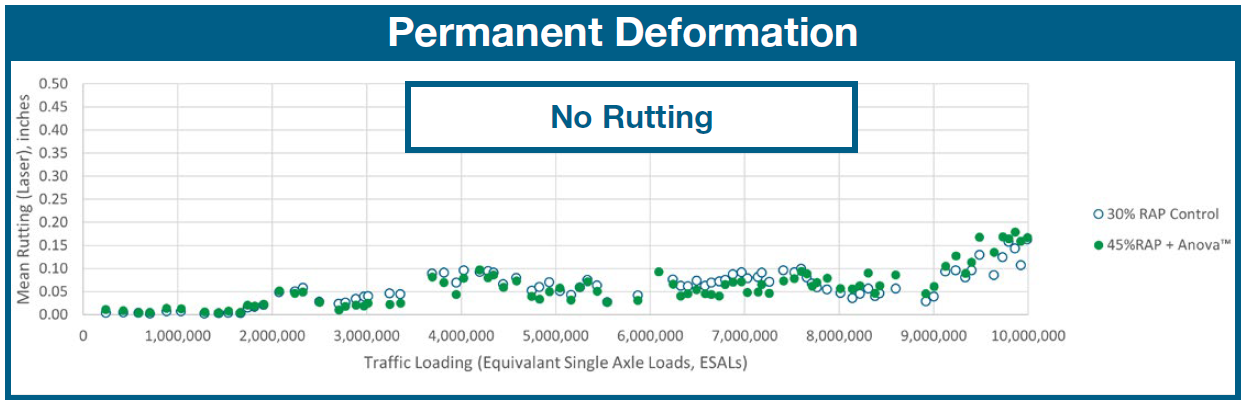

Now, after three years of testing and 10 million EASLs of loadings, test results show 0 percent cracking and no rutting damage. On average, the IRI index shows that the Anova® Rejuvenator section maintained ideal ride quality, perhaps even better than the control section. The impressive performance of the Anova 45% RAP section is shown in the following graphs.

The results of using Anova have shown a cost savings of $0.50 to $1.50 per ton on average compared to traditional mixes, which equates to approximately $750,000 in annual savings for a midsized contractor. These savings are achieved by using less virgin aggregate and less virgin asphalt. However, the benefits don’t stop at cost savings. An overall increase in mix workability and ease of compaction with Anova® mixes enables contractors to maximize their reliability and consistency in achieving target densities and potential associated bonuses.

“These results are going to be very impactful for the industry,” said Nam Tram, Assistant Director and Research Professor at NCAT. “These multi-generational results show that transitioning from standard volumetric to balance mix design asphalt should be considered as a consistent solution to meet industry performance, cost and environmental goals.”

Key Learning

This testing, along with the MnDOT project in a cold weather climate, will become one of the longest, most comprehensive Rejuvenated high-RAP mix tests.

“Five years is really that magic timeframe when we’ll have the most in-depth, consistent testing ever, examining the aging properties of binding materials,” said Powell.

The collaboration between the research facilities, state agencies and the private sector is providing a transparent, detailed assessment of the growing use of RAP nationwide, adding more credibility and trust in its use.

“We’ve looked closely at cracking, rutting and the macro texture over two years and it’s outperforming our expectations,” added Tran. “Our evaluation shows a flat texture still to this date with ravelling intact on the surface and sides of the road. This is exceptional at 45% RAP, which is outperforming the control at a lower level of RAP.”