Workplace Safety

Nothing matters more than the safety and wellbeing of our people. To ensure a safe and healthy workplace, we continue building on foundational programs that have, over the past several years, contributed to significant improvements in our overall safety results. In fact, many of our traditional metrics are the best they’ve ever been. Yet safety is a journey and one that calls for continuous focus, dedication and commitment.

Our commitments

Results as of May 31, 2023

Reportable Injury Frequency Rate (RIFR)* = 1.29

*RIFR: As defined by the U.S. Occupational Safety and Health Administration , the Reportable Injury Frequency Rate measures total recordable injuries per 200,000 hours worked. This metric at Cargill includes all injuries, not just those that result in lost workdays.

Our key programs and actions

Rather than introducing new safety programs, Cargill continues to enhance our foundational safety programming through our LIFE (Life-altering Injury and Fatality Elimination) program. The program, which was introduced in 2013, is aimed at identifying and addressing life-threatening dangers hidden in our tasks and workplace to ensure every job can be done safely and every person goes home safe every day.

Here are some components of our LIFE program:

LIFEsavers

LIFEsavers

LIFEsavers are the 12 activities that present the highest-risk to employees and contractors across all Cargill businesses. Each LIFEsaver identifies key risks and minimum requirements for performing these activities safely. By eliminating risks associated with these activities, we also eliminate the chances of serious injuries or fatalities. During this fiscal year, we implemented a new electrical safety program globally, designed to enhance the safety of our facilities and work practices.

Human and Organizational Performance (HOP)

We have been introducing a concept known as “human and organizational performance,” which helps companies better understand why injuries happen and how “systems thinking” helps build a strong and effective safety culture. Training on this concept is underway across the company and principles are being integrated into our day-to-day work, with the specific purpose of preventing human error and performing every job safely. Today, HOP training has reached tens of thousands of our people around the world, and deployment has gone global.

Leading metrics

Leading metrics

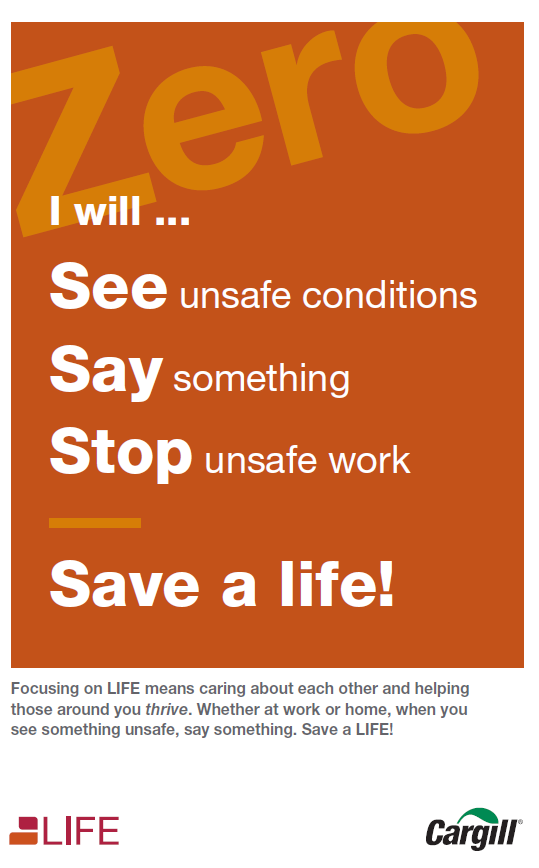

While our traditional lagging metrics are critical and tell us how effective our programs are, we’ve also introduced a series of “leading” metrics designed to help us see risks and take corrective, preventative actions before something bad happens. One of these leading metrics is our SIF-potential observation rate, which measures the frequency at which potential risks are reported and how well we protect against those risks. Our stop work authority program, SEE/SAY/STOP, feeds this metric and employees are embracing this opportunity to help make Cargill a safer company.

Safe driving

Global statistics are staggering. According to the World Health Organization, 1.2 million people die each year in roadway collisions. In Cargill, vehicle incidents are one of our leading causes of fatalities. That’s why vehicle safety is one of our 12 LIFEsavers. It’s also why we updated our Safe Driver policy to a total ban on mobile/cell phone use while driving on company time to minimize the risk of distracted driving. While we can’t eliminate all driving risks, this is a significant step toward keeping our people safer on the roads. As part of this updated safe driver policy, we’ve been working to eliminate the use of motorcycles for company business. To date, we have eliminated thousands of motorcycles from our operations and replaced them with safer modes of transportation for our people.