Soy Proteins

It takes innovation and creativity to develop high-quality food and beverages supporting health, convenience and well-being.

Positive consumer attitudes toward soy — and consumer demand for healthier foods — will drive new product growth for years to come. To help our customers across many categories, Cargill’s flexible, functional standard and Identity Preserved soy flours offer the following, all while ensuring a consistent final performance:

- texture improvement

- protein enhancement

- viscosity building

- water and oil management

- gelling properties

With soy protein plants in the U.S. — and relationships with farmers around the world — we help customers achieve the taste, mouthfeel functionality and nutrition profiles their customers want.

Working with our customers, we have developed a wide array of breads, baked goods, meats and other foods containing soy protein that promote health benefits. Contact us today for more information or a convenient sample.

In this section:

Functionality

The multiple functional properties of soy proteins make soy the preferred vegetable protein for food applications — a cost-effective and high-quality protein ingredient.

The functional properties of soy proteins depend on factors related to their physical and chemical properties. Understanding these properties requires detailed knowledge of the nature and structure of soy protein itself.

For example, functionality is affected by intrinsic factors (e.g. basic composition of the soybean), environmental factors (e.g. pH, salts, carbohydrates, lipids), and different processing treatments.

Protein Dispersability Index (PDI)*

This guide to functionality in soy protein products measures the level of protein that is soluble or suspended in water. Cargill Texturizing Solutions offer soy flour in four PDI designations:

90 PDI** – Minimal heat treatment, enzyme active

- Functions: crumb whitening, dough conditioning in bakery applications.

50 & 70 PDI** – Light heat treatment

- Functions: water absorption/retention; fat repulsion; protein enhancement; improved cell structure for baked goods, breads, pancakes, donuts, tortillas, bagels.

20 PDI** – Full heat treatment

-

Functions: water absorption/retention; flavor and protein enhancement.

(*) standard AOCS method for measuring heat treatment in soy processing

(**) Produced in the U.S.

Manufacturing

Manufacturing Soy Protein

The processing of soybeans starts with cleaning, cracking and dehulling. Cracked soybeans are rolled into full-fat flakes, which provide the basis for ground and powdered full-fat flour.

When oil is removed from full-fat soy flakes using solvent extraction, de-fatted soy flakes remain. These are the basis of a number of specialty functional ingredients such as soy flour, soy protein concentrate and soy protein isolate.

As an ingredient, the most elementary form of soy protein is soy flour. It has the highest level of protein:

- Full-fat soy flour contains 40% protein

- Defatted soy flour typically has 50 percent protein.

While more heat treatment usually means less functionality, new enzymatic and fermentation technologies now allow major modifications of protein properties.

Structure

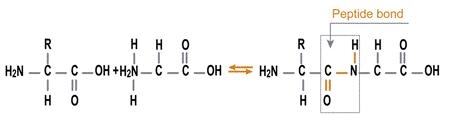

Proteins are highly complex organic compounds found in all living cells and comprising the most abundant class of all biological molecules. They are large molecules with high molecular weights, composed of varying amounts of amino acids, which in the intact protein are united through covalent chemical linkages called peptide bonds.

A protein with a molecular weight of 100.000 would contain about 850 amino acid residues. At least 20 of these amino acids are present in both plant and animal proteins. Amino acids are classified as essential (including dispensable), and conditionally essential (conditionally indispensable).

The amino acids, linked together, form linear unbranched polymeric structures called polypeptide chains. Such chains may contain hundreds of amino-acid residues, arranged in specific order for a given protein.

Reaction of amino acids to form a peptide bond

Soy Protein Molecular Structure

Depending on the source, the protein has a different structure and combination of amino acids in its chemical make-up. Every protein molecule has a characteristic, three-dimensional shape or confirmation that determines its properties.

Some Cargill products are only approved for use in certain geographies, end uses, and/or at certain usage levels. It is the customer's responsibility to determine, for a particular geography, that (i) the Cargill product, its use and usage levels, (ii) the customer's product and its use, and (iii) any claims made about the customer's product, all comply with applicable laws and regulations.