Infographic

Carrageenan

Carrageenans are polysaccharides (galactose) with varying degree of sulfatation (between 15% and 40%). They are extracted from red seaweeds and are used as thermo reversible gelling agents and thickening agents. Carrageenans can control syneresis. Carrageenans can also be used as a binding agent and can improve texture and mouthfeel. Cargill is a supplier of carrageenan for the food industry.

Types of carrageenan

In general, three major types of carrageenans can be distinguished:

- Alcohol processed refined carrageenans.

- Potassium chloride processed refined carrageenans.

- Semi-refined carrageenan, also called PNG (Philippine Natural Grade) or PES (Processed Eucheuma Seaweed). This has only more recently been approved for food applications.

Applications

Dairy

- Dairy Desserts (like gelled milks, flans, multi-layered desserts, mousses)

-

Ice Cream

- In combination with guar gum, locust bean gum and alginates

-

Powder Products:

- Dessert, Custard and Bakery Creams

- Homemade Flans

- Water Gel Desserts, Glazings

- Stabilization of Chocolate Drinks and Creams

Meat & Fish

-

Injections (hams, poultry)

- Canned Foods (in combination with locust bean gum for human and pet food)

- Fat Reduction (hamburgers)

Functionality

Structuring using carrageenan

Gelling carrageenans: kappa and iota

After undergoing the heat treatment required for dissolution, the macromolecules in carrageenan have a tendency to spontaneously associate during cooling, thus creating junction zones required for a gel.

The iota carrageenan network is formed by a series of double-helices and kinks that form a transparent, elastic gel. This loosely-connected network can easily be destroyed by mechanical action. However, it reforms quickly once the mechanical action has stopped.

This property is called "thixotropy" and is very useful in certain applications such as cold-filled dairy desserts.

Gelation of kappa carrageenan is particularly enhanced by the potassium ion. It induces gel formation at very low concentrations.

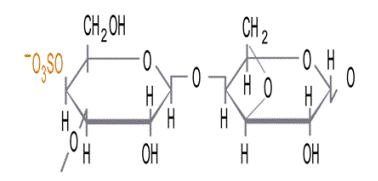

KAPPA (κ) 1 SULFATE FOR 2 SUGAR UNITS

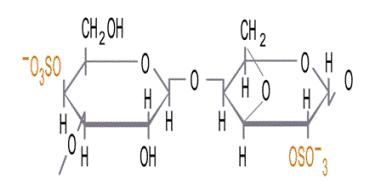

IOTA (ι) 2 SULFATE FOR 2 SUGAR UNITS

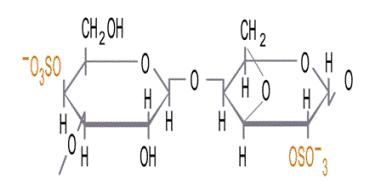

IOTA (ι) 2 SULFATE FOR 2 SUGAR UNITS

Thickening carrageenans: lambda

Mainly because of electrostatic repulsion, the chains of lambda carrageenan do not have a tendency to self-associate and can easily be separated from each other. Thus, lambda carrageenan acts simply as a thickening agent.

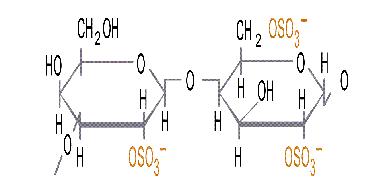

LAMBDA (λ) 3 SULFATE FOR 2 SUGAR UNITS

The structures described above are idealized implying that different carrageenans are perfect chains made up of identical repetitive units. In reality, carrageenan macromolecules are not homogeneous. They are heterogeneous either due to differing molecular structures within the chains or due to differing chains within the seaweed. For example, some carrageenans extracted from South American seaweeds are kappa and iota hybrids which may be called kappa 2 or weak kappa carrageenans.

Regulatory

European legislation clearly distinguishes carrageenan (E 407) from Processed Eucheuma Seaweed (P.E.S.) (E 407a - a semi refined carrageenan as described below), using the acid insoluble matter as the main criteria for differentiation.

FAO/WHO - Codex Alimentarius

Carrageenan and P.E.S. have been given an Acceptable Daily Intake (ADI) of “not specified” by the FAO/WHO Joint Expert Committee on Food Additives (JECFA).

European Union

Carrageenan (E 407) and P.E.S. (E 407a) are listed in Annex I of the European Parliament and Council Directive 95/2/EC of 20th February 1995 on food additives, and may be used at “quantum satis” in many food categories.

United States

The FDA recognizes carrageenan and P.E.S. as permitted for direct addition to food for human consumption in the Code of Federal Regulations (CFR 21, § 172.620).

Cargill's global team of regulatory and food law experts will be glad to provide assistance on regulatory, nutrition-related claims and food law-related issues.

Some Cargill products are only approved for use in certain geographies, end uses, and/or at certain usage levels. It is the customer's responsibility to determine, for a particular geography, that (i) the Cargill product, its use and usage levels, (ii) the customer's product and its use, and (iii) any claims made about the customer's product, all comply with applicable laws and regulations.