Airshaft Update

Construction Update: Cayuga Mine #4 Shaft Project

February 2021

Work in January included:

•Continued shaft fitment and prep for final use

Through February, shaft fitment will remain on a Monday through Saturday, 24 hours per day schedule. Shaft fitment is expected to continue through March. Surface work will continue a 7 AM to 7 PM Monday through Friday schedule.

Cayuga Mine No. 4 Project Site, January 2021

Construction Update: Cayuga Mine #4 Shaft Project

January 2021

Work in December included:

•Continued shaft fitment and prep for final use

•Interior plumbing and HVAC

Through January, shaft fitment will remain on a Monday through Saturday, 24 hours per day schedule. Shaft fitment is expected to continue through March. Surface work will continue a 7 AM to 7 PM Monday through Friday schedule.

Cayuga Mine No. 4 Project Site, December 2020

Construction Update: Cayuga Mine #4 Shaft Project

December 2020

Work in November included:

•Shaft fitment and prep for final use is on-going.

•Whitmore Fence finished perimeter fencing.

•All buildings are currently temperature controlled.

•Interior plumbing work.

Through December, shaft fitment will remain on a Monday through Saturday, 24 hours per day schedule. Shaft fitment is expected to continue through February. Surface work will continue a 7 AM to 7 PM Monday through Friday schedule.

Cayuga Mine No. 4 Project Site, November 2020

Construction Update: Cayuga Mine #4 Shaft Project

November 2020

Work in October included:

•Shaft fitment and prep for final use is on-going.

•Whitmore Fence back onsite to wrap up final site fencing.

•Installed final HVAC duct work and plumbing in the maintenance building.

•HVAC work in the administrative building.

•Conducted additional paving around the collar house

In November, shaft fitment will remain on a Monday through Saturday, 24 hours per day schedule. Shaft fitment is expected to continue through December. Surface work will continue a 7 AM to 7 PM Monday through Friday schedule.

Grass from the fall seeding program is coming in well along the driveway.

Construction Update: Cayuga Mine #4 Shaft Project

October 2020

Work in September included:

•Continued the shaft lining process.

•Completed 3 liner pours.

•Lined an additional 106’ of the shaft.

•Shaft lining is 100% complete.

•Completed the construction of the ventilation sweep underground and tied it into the bottom of the shaft liner.

•LRS continued laying final topsoil and seeding work.

In October, shaft fitment will continue Monday through Saturday, 24 hours per day . The fitment phase encompasses installing the shaft steel and equipment required for guiding the elevator cage in the shaft. Shaft fitment is expected to continue through December.

Final seeding work on the roadside drainage systems.

| Screening topsoil onsite to use for final grading and planting. |

Construction Update: Cayuga Mine #4 Shaft Project

September 2020

Work in August included:

•Continued the shaft lining process.

•Completed 12 liner pours.

•Lined an additional 480’ of the shaft.

•Shaft lining is 94% complete.

•Shaft steel has begun arriving on site.

•LRS began laying and grading topsoil in preparation for fall seeding.

Shaft lining work will be completed by early September. In mid-September, shaft fitment will begin on a 24 hour per day schedule Monday through Saturday. The fitment phase encompasses installing the shaft steel and equipment required for guiding the elevator cage in the shaft. Shaft fitment is expected to take approximately 3 months.

Shaft guides arriving on-site.

Atlantic Testing Laboratories collecting concrete sample for quality testing.

Construction Update: Cayuga Mine #4 Shaft Project

August 2020

Work in July included:

•Continued the shaft lining process.

•Completed 9 liner pours.

•Lined an additional 360’ of the shaft.

•Shaft lining is 74% complete.

•Continued work on the septic system, site drainage, and environmental systems.

•The raisebore drill was fully demobilized from the site.

Shaft lining work will continue in August on a single shift with typical hours of 5AM-5PM, Monday-Saturday. This work may shift earlier or later depending on weather and progress. Shaft lining and fitment is expected to continue through the summer and into fall.

Miners entering shaft for shaft lining.

Construction Update: Cayuga Mine #4 Shaft Project

July 2020

Work in June included:

-

Continued the shaft lining process.

- Completed 20 liner pours.

- Lined an additional 730’ of the shaft.

- Shaft lining is 58% complete.

- Continued work on the septic system, side walks, site drainage, and grading.

No work is planned for July 3rd through July 6th. For the remainder of the month shaft lining will continue on a single shift with typical hours of 5AM-5PM, Monday-Saturday. This work may shift earlier or later depending on weather and progress. Shaft lining and fitment is expected to continue through the summer and into fall.

Cement truck filling the bucket for a liner pour.

Filling the concrete bucket.

Community Support

July 2020

Due to the on-going pandemic Cargill recognized the high level of need to provide meals in our communities. Over the past few months, Cargill has made the following donations to support our communities:

- $40,000 for the Lansing Food Pantry

- Lansing and Watkins Glen worked together to provide $70,000 to the Food Bank of the Southern Tier which provides food for Broome, Chemung, Schuyler, Steuben, Tioga, and Tompkins Counties.

- $10,000 for the King Ferry Food Pantry

- $5,000 for the Dryden Family Meal Connection

Construction Update: Cayuga Mine #4 Shaft Project

June 2020

Work in May included:

- Commissioned the hoists and winches used in shaft lining.

-

Began lining the shaft.

- Completed 17 liner pours.

- Lined 676’ of the shaft (28%).

- Continued work on the septic system, site drainage, and grading.

Shaft lining will continue on a single shift with typical hours of 5AM-5PM, Monday-Saturday. This work may shift earlier or later depending on weather and progress. Shaft lining and fitment is expected to continue through the summer and into fall.

Drill bit removed. Temporary headframe roped up for shaft lining.

Construction Update: Cayuga Mine #4 Shaft Project

May 2020

Work in April included:

- Raisebore drilling of the shaft was completed on April 22nd, 2020.

- Demobilized the shaft drill and drill bit from the shaft foundation.

- Installed the temporary deck and headframe that will be used for shaft lining.

- Lowered the formwork and work deck into the shaft that will used for shaft lining.

- Began rope up and final commissioning of the hoists and winches that will used in shaft lining.

Shaft lining will begin the week of May 4th and will be conducted on a single shift per day. Typical shaft lining hours will be 5AM-5PM, Monday-Saturday, but may shift earlier or later depending on weather and progress. The concrete liner will be placed in 40’ lifts, which take 9 to 10 concrete trucks per pour. Total shaft lining time is estimated at approximately 5 months.

Temporary headframe for shaft lining.

Construction Update: Cayuga Mine #4 Shaft Project

April 2020

Work in March included:

- Installed siding and roof trim on the surface buildings.

- Ongoing interior work on the hoist house, maintenance building, and administrative building.

- Began construction on the concrete entry pads to the buildings and the sidewalks.

- Began construction of the collar house foundation. The collar house is the building that encloses the shaft.

- Raisebore drilling of the shaft continued in March and was 60% complete by the end of the month.

Although Cargill is an essential business, due to the ongoing COVID-19 virus, all work not directly related to the ongoing shaft drilling, shaft lining, and environmental systems will be suspended at least until April 15. The surface work will be wound down until the site is secured.

Collar house foundation under construction.

Construction Update: Cayuga Mine #4 Shaft Project

March 2020

Work in February included:

- Installed the roof panels on the administrative and maintenance buildings.

- Installed windows and doors on the hoist house.

- Ongoing interior work on the hoist house, maintenance building, and administrative building.

- Raisebore drilling of the shaft started in early February and was 25% complete by the end of the month. The shaft is being drilled at 16’ diameter, from the bottom up. Drilling is expected to continue on a 24-hour-per-day operation, Monday through Saturday throughout March and April.

Surface work will continue in March on a Monday through Friday (7AM – 7PM) schedule. This work will include:

- Installation of trim, windows, and doors on the buildings.

- Interior work on the buildings.

- Forming and pouring of the collar house foundation.

Raisebore drill.

Roofing panels being installed on the maintenance building.

Construction Update: Cayuga Mine #4 Shaft Project

February 2020

Work in January included:

- Installed the roof trusses and roof decking on the administrative building.

- Installed the roof and wall panels on the hoist house.

- Ongoing interior work on the hoist house, maintenance building, and administrative building.

- Completed the pilot hole drilling and moved the pilot hole drill rig off the shaft foundation.

- Assembled the raisebore drill on the shaft foundation and began tripping in drill rods.

Surface work will continue in February on a Monday through Friday (7AM – 7PM) schedule. This work will include:

- Installation of roof panels and siding trim on administrative and maintenance buildings.

- Interior work on the buildings.

Drilling of the raisebore is expected to start during the first week of February. This drilling is schedule for 24 hour per-day operation, Monday through Saturday and is expected to take approximately three months.

Raisebore drill adding drill steels and the hoist house under construction.

Admin Building Interior with trusses installed.

Construction Update: Cayuga Mine #4 Shaft Project

January 2020

Work in December included:

- Continued block wall construction on the administrative building, including starting the interior block walls.

- Installed the roof decking on the hoist house.

- Installed the wall panels on the maintenance building.

- Continued pilot hole drilling. Pilot hole is approximately 60% complete.

Surface work will continue in January on a Monday through Friday (7AM – 7PM) schedule. This work will include:

- Installation of the roof trusses on the administrative building.

- Continued installation of roof and wall panels on the hoist house and administrative buildings.

- Continued drilling of the pilot hole.

Starting January 8th, pilot hole drilling will move to 24 hour per-day operation, Monday through Saturday. The pilot hole is expected to be completed by the end of January.

Maintenance Building – Wall panels installed

Admin Building Interior – Looking South

Construction Update: Cayuga Mine #4 Shaft Project

December 2019

Work in November included:

- Began construction of the block walls, installed the sub-grade plumbing, and poured the floor for the administrative building.

- Installed the block walls and installed the structural steel for the hoist house.

- Set-up the pilot hole drill and began drilling the pilot hole.

- Revised a neighbor well-monitoring program.

Work will continue in December on a Monday through Saturday (6AM – 9PM) schedule. This work will include:

- Construction of the block walls and structural steel on the administrative building.

- Wall and roof panel installation on the hoist house, maintenance building, and admin building.

- Continued drilling of the pilot hole.

No work is currently planned from December 24th, 2019, through January 1st, 2020.

Administration Building Progress

Pilot Hole Drill

Construction Update: Cayuga Mine #4 Shaft Project

November 2019

The pilot hole drill and components have begun to arrive on site and will be tested early in the month of November. Drilling of a pilot hole for the new mine shaft is scheduled to start the week of November 11th and is expected to take approximately 40 days to complete. Drilling will be on a 12-hour-per-day drill schedule, Monday through Saturday. The specialty electric mud pump has arrived. This pump is a quiet alternative to typical diesel pumps.

Work in October included:

- Finalized the substation installation and brought it online.

- Construction of the headframe back leg foundations are complete.

- Installation of the hoist mechanicals.

- Construction of the administrative building foundation.

- Construction of the maintenance building wall columns, roof trusses, and roof decking.

- Mobilizing drill components to the site.

Surface work will continue in November on a Monday through Friday (7AM – 7PM) schedule. This work will include:

- Construction of the block walls on the hoist house and administrative building.

- Installation of steel and trusses on the hoist house.

- Finalize backfilling around the shaft foundation.

Administration Building Foundation

Hoist Installation

Maintenance Shop Framing

Headframe Back-leg Foundation

Construction Update: Cayuga Mine #4 Shaft Project

October 2019

Shaft construction is tentatively scheduled to start the last week of October with the drilling of a 2,500 feet deep pilot hole for the shaft. The pilot hole is expected to take 40 days to complete, running on a 12-hour per day drill schedule, Monday through Saturday. A specialty electric pump will be utilized instead of the typical diesel pump in order to minimize drilling noise.

Work in September included:

- Began waterproofing, backfilling, and compacting the shaft foundation. The backfill is 60% complete.

- Continued wiring and testing of the electrical substation equipment.

- Formed, added rebar, and poured the hoist foundation and the hoist house foundation.

- Installed the septic tank and began constructing the absorption areas.

- Built the block wall base for the maintenance building.

Surface work will continue in October on a Monday through Friday (7AM – 7PM) schedule. This work will include:

- Finalizing the substation installation and bringing it online.

- Construction of the headframe back leg foundations.

- Installation of the hoist.

- Construction of the administrative building foundation.

- Construction of the maintenance building wall and roof systems

Shaft Foundation Partially Backfilled

Septic Tank Installation

Construction Update: Cayuga Mine #4 Shaft Project

September 2019

Work in August included:

- Formed and poured the remaining 2 sections of the concrete shaft foundation.

- Set the substation equipment and began wiring it.

- Formed the hoist foundation and made the first of 2 pours.

- Began excavating for the hoist house foundation.

Surface work will continue in September on a Monday through Friday (7AM – 7PM) schedule. This work will include:

- Backfilling outside the shaft foundation.

- Wiring and installation of substation equipment.

- Construction of the hoist and hoist house foundations.

- Construction of the headframe back-leg foundations.

- Septic system construction.

Adding rebar for the hoist foundation

Transformer set on pad

Pouring the last wall of the shaft foundation

Construction Update: Cayuga Mine #4 Shaft Project

August 2019

Work completed in July:

- Continued final site grading and began seeding.

- Formed and poured 2 out of the total 4 sections of the concrete shaft foundation.

- Site fencing is now 75% complete.

- Began installing substation equipment.

- Formed and poured the maintenance shop foundation.

Surface work will continue in August on a Monday through Friday (7AM – 7PM) schedule. This work will include:

- Forming and pouring of the concrete shaft foundation.

- Wiring and installation of substation equipment.

- Final grading and seeding.

- Construction of the maintenance shop.

Shop foundation formed and poured

Pond area final grade and seeded

Pouring the shaft foundation

Construction Update: Cayuga Mine #4 Shaft Project

July 2019

Work completed in June:

- Continued final site grading.

- Installed rebar and formwork for the shaft foundation.

- Installed fence posts for the final site fencing.

- Installed foundations for the new transformers in the electrical substation.

Surface work will continue in July on a Monday through Friday (7AM – 7PM) schedule. This work will include:

- Forming and pouring of the concrete shaft foundation.

- Installation of the electrical substation and systems.

- Site grading

Pouring substation foundations

Shaft foundation in progress

Form work delivered to site

Construction Update: Cayuga Mine #4 Shaft Project

June 2019

Work completed in May:

- Site grading continued and is now 90% complete.

- The shaft foundation was excavated down to bedrock.

- Began installing rebar for the shaft foundation.

- The main entrance road was widened and graveled.

Surface work will continue in June on a Monday through Friday (7AM – 7PM) schedule. This work will include:

- Forming and pouring of the concrete shaft foundation.

- Installation of the electrical substation and systems.

- Installation of additional site fencing.

Entrance road upgrades in progress

Shaft foundation excavated to bedrock

Construction Update: Cayuga Mine #4 Shaft Project

May 2019

Dirt work and rough grading began in April, with the installation of the erosion control and storm water pond systems. The electrical cable for mine power was also installed into the recently drilled borehole.

Surface work will continue in May on a Monday through Friday (7AM – 7PM) schedule. This work will include:

- Grading of the parking lots

- Creating onsite service roads

- Excavation and construction of the shaft collar/foundation

- Installation of the electrical substation

Dirt work in progress

Cable being prepped for lowering

Construction Update: Cayuga Mine #4 Shaft Project

April 2019

With spring upon us, dirt work is scheduled to start in early April. Initial dirt work is expected to take approximately 6 weeks and will include upgrades to the entry road, construction of the drainage system and ponds, and rough grading of the site. Excavation work will be completed by LRS Excavating of Lansing, NY and is scheduled for 7AM through 7 PM, Monday through Friday.

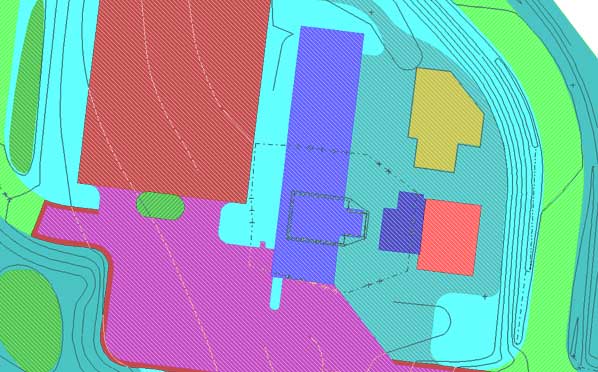

Rough grading plan. Site excavation equipment will utilize GPS for increased accuracy.

Construction Update: Cayuga Mine #4 Shaft Project

February 2019

Drilling of the power borehole is complete and the equipment is being demobilized from the site. This 2,500’ deep by 8” diameter fully cased hole will be used to bring power into the mine closer to the working areas. NYSEG has also completed the power install to the site. In the coming months, LRS Excavating of Lansing, NY will start the site grading and HMT of Cicero, NY will start the substation installation.

NYSEG Installing a Power Pole

Drill Rig Setup

Construction Update: Cayuga Mine #4 Shaft Project

December 2018

Cargill has installed an above grade drill pad and is currently drilling an 8” finished drill hole. This borehole will be utilized for bringing power into the mine. Drilling is scheduled for 7AM to 7PM and is expected to wrap up by early February. Environmental controls are in place at the site.

Drill pad under construction

Main drill arrives on site

Drilling for the surface casing

Construction Update: Cayuga Mine #4 Shaft Project

October 2018

Cargill has begun installing the environmental controls at the #4 Shaft site. The controls include silt fencing around the construction site, a tie in at the road, and a construction entrance for minimizing dirt tracked onto the road. In the coming months general site grading will begin, with LRS Excavating, Inc. of Lansing conducting the work.

Silt fencing installed along the northern border of the driveway

Site surveying has been done to lay out features and facilities

Construction entrance work underway

Tapping the main for water

Town of Lansing Board Awards the Special Use Permit for the #4 Shaft Project to Proceed

January 2018

Following a public hearing on December 20, 2017, the Town of Lansing Board awarded the Special Use Permit for the 1001 Ridge Road site with a unanimous 5-0 vote. Next, Cargill will apply for the required Building Permits and expects to begin construction in early 2018.

Below are a few of the public comments made by Cargill employees during the public hearings for this project. They talk about why this project is important to them, the mine, and the community:

Video commenters include Adam Rossbach, production miner, Brian Bartlett, general foreman, and Doug Smith, hoist operator.

Town of Lansing Planning Board Awards Conditional Site Plan Approval

October 2017

The Town of Lansing Planning Board awarded conditional Site Plan Approval for the site with a unanimous 7-0 vote.

See the video for a recap of the presentation that Cargill presented at the Site Plan Approval Public Hearing. It includes an overview of the project, including environmental assessment findings:

Department of Environmental Conservation Approves Permit Amendment Application For A New Air Shaft

|

Cargill has received a mine permit amendment from the New York State Department of Environmental Conservation (NYSDEC) to expand the surface operation by adding a new air shaft and the associated surface facilities in support of the new shaft. The facility is located at 1001 Ridge Road, (NYS RTE 34 B), Tompkins County, New York. Background information on Shaft and Surface Facility ConstructionThe modification involves the construction of a surface access and ventilation shaft for the safety of the miners, decreasing the distance from the current underground operations to the new air shaft. The new air shaft will be constructed using standard drilling techniques. The surface facilities will be built in conjunction with the shaft. Temporary and permanent storm water controls will be constructed in phases with facility construction. Best management practices and mitigation measures will be implemented to minimize potential environmental impacts. Other features of the new air shaft project include:

|

Mine Permit RenewalsIn 2003, the New York Department of Environmental Conservation issued a mining permit renewal to Cargill Deicing Technology to expand and continue operation of the Cayuga Mine. The permit authorizes continued activity principally beneath Cayuga Lake. The processing equipment is located underground, but all salt storage facilities are on the surface at the current mine site. This mine is the deepest underground salt mine in the western hemisphere In 2008, the state evaluated and renewed the mine permit. In 2015, the state approved an amendment to Cargill’s existing mining permit to add an additional 150 acres to the existing subsurface mining area. The new acres are contiguous to the existing mine. |