Food Processing Salt Crystal Varieties

Understanding the differences between popular food processing salts and their methods of production.

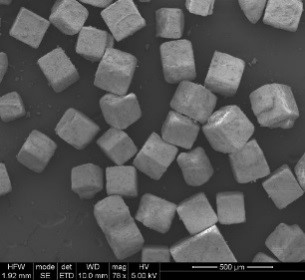

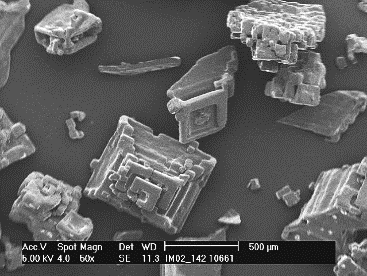

Granulated Salt is produced by the mechanical evaporation of brine. Water is pumped into an underground salt deposit, dissolved to form a brine, and boiled to evaporate water and cause the salt crystals to form. Cargill carries a versatile portfolio of granulated salts, available in an wide selection of grades and screens – with or without additives – and is ideal for a wide variety of food processing applications.

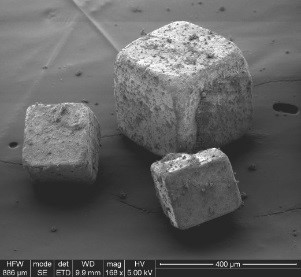

Sea Salt is salt produced from a living sea. Cargill’s sea salt is produced in California from the waters of the Pacific Ocean, rather than a dried-up sea bed. It’s Made Naturally with Sun, Wind, and Time® in large, shallow ponds. The food-grade sea salt is then washed, dried, and ground to customer specifications. Cargill’s sea salt is available in a wide selection of grades and screens – with or without additives – and is ideal for a wide variety of food processing applications, such as baking, seasonings, meats, and more.

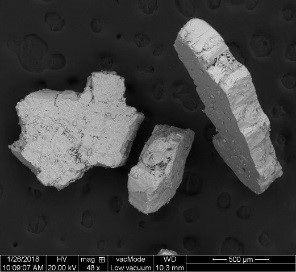

Flake Salt is granulated salt that has been processed and compacted to create a unique flaked shape. This product has a larger surface area, resulting in better adherence, solubility, and blendability compared to granulated salt. Cargill’s flake salts are available in a wide selection of grades and screens – with or without additives – and are ideal for multiple food processing applications, including seasonings, koshering, topical, and more.

Alberger® Flake Salt is produced by Cargill’s proprietary Alberger method. Brine is slowly heated and gently agitated in an open-pan evaporation process, allowing for hollow pyramid-shaped crystals to form. This unique crystal shape gives Alberger® Salt its superior sensory benefits, rapid solubility, strong adherence, and lower bulk density. It can also provide up to 50% lower sodium by volume vs. granulated salt. Cargill’s Alberger® Flake Salts are available in a wide selection of grades and screens – with or without additives – and are ideal for multiple food processing applications, including baking, meats, cheese, seasonings, koshering, topical, and more.

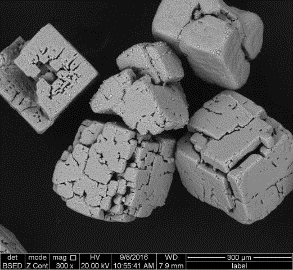

Dendritic Salt is produced by adding a crystal modifier, such as yellow prussiate of soda, to the brine during mechanical evaporation. The crystal modifier interferes with the native crystal growth, resulting in a more porous irregular-shaped crystal structure and a low bulk density salt. Cargill does not produce this type of salt.