Study: How Alberger® Salt can Reduce Sodium & Maintain Taste

In an evolving consumer landscape, food companies must find a way to balance the priorities of taste and nutrition - which is much easier said than done.

One of the biggest concerns food manufacturers have when attempting to reduce sodium in their products is maintaining flavor parity. This comes as no surprise since taste remains the top driver of consumer food and beverage purchases. Even so, the gap in prioritization of taste over healthfulness of foods is closing more and more each year as demand for more nutritious products increases (1). With this evolving consumer landscape, food companies must find a way to balance the priorities of taste and nutrition--which is much easier said than done. That’s why at Cargill Salt, we’ve invested in providing the ingredients, resources, and expertise to enable food manufacturers to reduce sodium levels while maintaining the integrity of their products.

There are a variety of approaches food manufacturers can take to reduce sodium content in products. One widely used method is to reformulate with potassium chloride, a common “salt” ingredient that contains potassium in place of sodium. Potassium chloride is often a go-to solution to reduce sodium because it helps maintain the flavor and functional benefits of salt (sodium chloride) and can be used as a 1:1 substitution in the production line. To help address the increased demand for potassium chloride as a salt replacer, Cargill Salt recently opened a new potassium chloride facility, making Cargill the only food company to domestically produce food-grade potassium chloride in the United States. This increased manufacturing capability enables us to bring new solutions to market faster, making Cargill an ideal potassium chloride provider. (2)

Another simple strategy for reducing sodium levels in food is reformulating with Alberger® Brand Flake Salts, a line of proprietary Cargill products produced in St. Clair, MI. Alberger® Salts get their name from the unique Alberger process that creates flaky, multi-faceted crystals instead of hard cubical grains—the shapes produced by other salt-making methods. The natural process to create Alberger® Salts is what gives them their unique characteristics and enables their use as sodium reducing ingredients. Because of the hollow, pyramid-like crystal shape of Alberger® Salts, food manufacturers can use less and achieve up to 33% lower sodium per volume compared to typical granulated table salt.

Not only can the use of Alberger® Salt lower sodium levels in foods, but it does so with just a single ingredient switch and no change in ingredient declaration. And importantly, making the switch may not only maintain flavor and other functional benefits of salt, but it could even bolster these characteristics in some cases. One 2018 study conducted by Cargill Salt’s Technical Services Team uncovered just that when testing sodium reduction in cracker dough. (3)

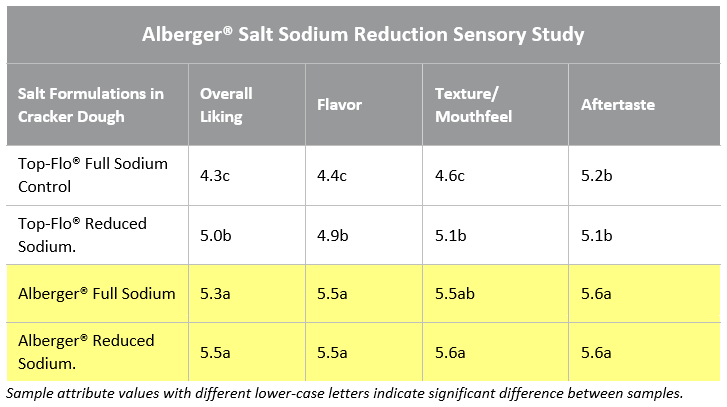

When comparing our Alberger® Flour Salt with standard granulated table salt, Alberger® Salt ended up scoring significantly higher for all attributes tested. The study objective was to decrease salt levels in cracker dough by 40% to achieve a 22% sodium reduction. All samples were equally formulated with only salt being the varying factor (3). The four samples were precisely formulated and then brought before a sensory panel to be evaluated in a randomized fashion:

- Top-Flo® Full Sodium – control: Fully-salted cracker formulated with granulated salt.

- Top-Flo® Reduced Sodium – 60% of the control’s salt level: 22% reduced sodium cracker formulated with granulated salt.

- Alberger® Full Sodium – 100% of control’s salt level: Fully salted cracker formulated with Alberger® Flour Salt.

- Alberger® Reduced Sodium – 60% of control’s salt level: 22% reduced sodium cracker formulated with Alberger® Flour Salt.

Panelists were asked to rate each sample based on four attributes – overall liking, flavor, texture/mouthfeel, and aftertaste – using a 9 point hedonic scale (1 = “Dislike Extremely” ; 9 = “Like Extremely). Food scientists then evaluated the statistical significance for each measured attribute between each sample, using p < 0.05. Letters that are the same in each column mean the numbers associated with them are not significantly different, and letters that are different in each column mean that the numbers associated with them are significantly different.

Between the full sodium and reduced sodium standard Top-Flo® granulated samples, there was quite a bit of variation in scores for all the attributes except aftertaste. However, between the full sodium Alberger® and reduced sodium Alberger® samples, there was no significant difference between samples for all attributes tested. This is great news for food manufacturers who want to prioritize both taste and sodium reduction. In addition, both Alberger® samples obtained significantly better scores than either of the Top-Flo® granulated salt samples for flavor, texture/mouthfeel, aftertaste, and overall liking. This just goes to show that not all salts are created equal, and the salt that food manufacturers choose could significantly alter the overall perceptions of their products. (3)

To learn more about Cargill Salt’s sodium reduction solutions, visit https://www.cargill.com/food-beverage/na/sodium-reduction-solutions or call 1-888-385-SALT (7258).

Sources:

- https://www.feedstuffs.com/news/food-values-driving-consumer-decision-making

- https://www.cargill.com/salt-in-perspective/potassium-pro-potassium-chloride

- Cargill Proprietary: Sensory Comparison Study – Sodium Reduction in Cracker Dough, Sensory Report 1325