Higher flash and fire points for improved fire safety

When it comes to fueling transformer pool fires, FR3 dielectric fluid gets a big zero, while mineral oil’s link to catastrophic failures is too great. When equipment, power outages, and lives are at stake, zero obviously wins.

Improved fire safety can benefit your business and community. Get FR3 fluid details.

A safer, better choice. More peace of mind.

Whether your transformers are in densely populated, frequently crowded areas—such as urban neighborhoods, suburban malls, university campuses, or corporate headquarters—or are in more remote places, transformer fires are costly, and not just in terms of money.

Whether your transformers are in densely populated, frequently crowded areas—such as urban neighborhoods, suburban malls, university campuses, or corporate headquarters—or are in more remote places, transformer fires are costly, and not just in terms of money.

Although transformers are generally very reliable machines, transformer pool fires involving mineral oil transformer fluid are NOT rare events. For every 400 mineral-oil-filled transformers, we can expect one or two catastrophic failures every two years.1 Since the number of mineral-oil-filled transformers in continuous operation in any country exceeds several million, even a failure rate of fraction of a percent a year leads to many failures each day. And these failures can lead to power outages, equipment damage or loss, and even loss of human life.

When you fill transformers with FR3 fluid instead of mineral oil transformer fluid, you drastically reduce the chance—even to zero—of catastrophic failure with external consequences.

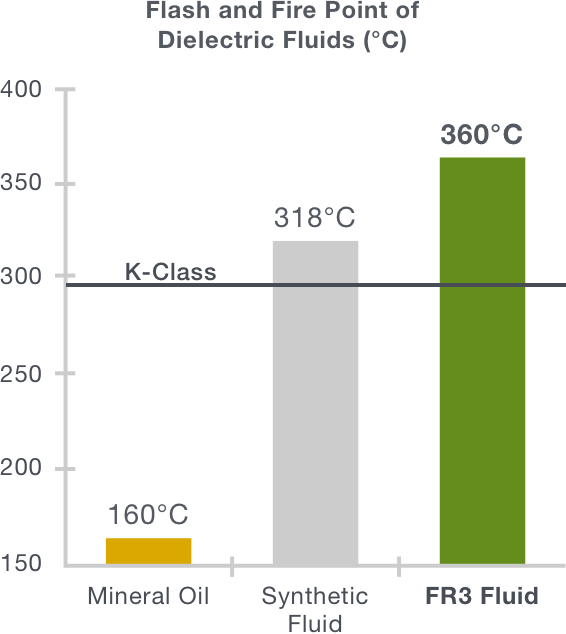

FR3 fluid’s flash and fire points (330°C and 360°C, respectively) are more than twice those of mineral oil transformer fluid (155°C and 165°C, respectively).

Unlike mineral oil, FR3 fluid is classified as a K-class, “high-fire-point,” “fire-resistant,” and “less-flammable” fluid. Also classified as “nonpropagating,” it is self-extinguishing, and will not continuously burn if ignited. Mineral oil, however, will keep burning for hours when ignited, with no way to stop it until all the oil is consumed.

FR3 fluid is UL classified2 and FM Global approved.3 For most installations, FM Global recognizes FR3 fluid as a safeguard equivalent to space separation, fire barriers, and fire suppression systems, based on hot-metal and large-scale arc ignition tests.

NEC standards permit FR3-fluid-filled transformers to be installed indoors without fire-suppression sprinkler systems or vaults, and with minimum wall clearance of only 3 feet (0.9M).4

What this all means

FR3 fluid is a significantly safer and better choice compared to mineral oil transformer fluid. Using FR3 fluid in your distribution and power generation transformers helps you AVOID:

|

Equipment damage or destruction Environmental damage and remediation Unscheduled service outages |

Asset repair or replacement Human injury or casualty Community unease and negative publicity |

And using FR3 fluid ALLOWS you to:

- Reduce clearance requirements to buildings and equipment.

- Eliminate the need for costly fire-mitigation systems.

- Potentially reduce insurance premiums and liability service.

- Improve grid reliability.

Find out how using FR3 fluid positively effects total cost of ownership.

The Advantage of K-Class Fluids for Electrical Installations (2019)

Learn the design implications of FR3 fluid’s reduced fire risk relative to mineral oil.

Proactive Fire Safety for Transformer (2013)

Get data and information about quantifying the risk of miner-oil-filled transformer failure.

FR3® Dielectric Fluid Data Sheet

Get technical details about FR3 fluid, including functional specifications.

1. “A Worldwide Transformer Reliability Study,” Cigré Working Group A2.37, 2015. The report defines “catastrophic failure with external consequences” as a failure involving fire, explosion, and oil spillage, and as requiring the removal of the transformer from service for longer than sever days for investigation, repair, or replacement

2. Underwriters Laboratories (UL), EOVK—Dielectric Mediums—and EOVK—Transformer Fluids—UL Listed and Classified Products, Underwriters Laboratories, Northbrook, IL, USA.

3. Factory Mutual Insurance Company (FM Global), Less-Flammable Transformer Fluids, Approval Guide—Electrical Equipment, FM Approvals, FM Global, Norwood, MA, USA.

4. When the construction is 1-hour fire rated or using FM-approved transformers. OSHA recognizes FM Global Standard 3990, which recognizes FR3 fluid as a component of Approved transformers, as fitting the definition of a Listed and Labelled Product per NEC Section 110-3(b).

The products and services described on this website may not be available in all jurisdictions or to all persons.