FR3® fluid technical details

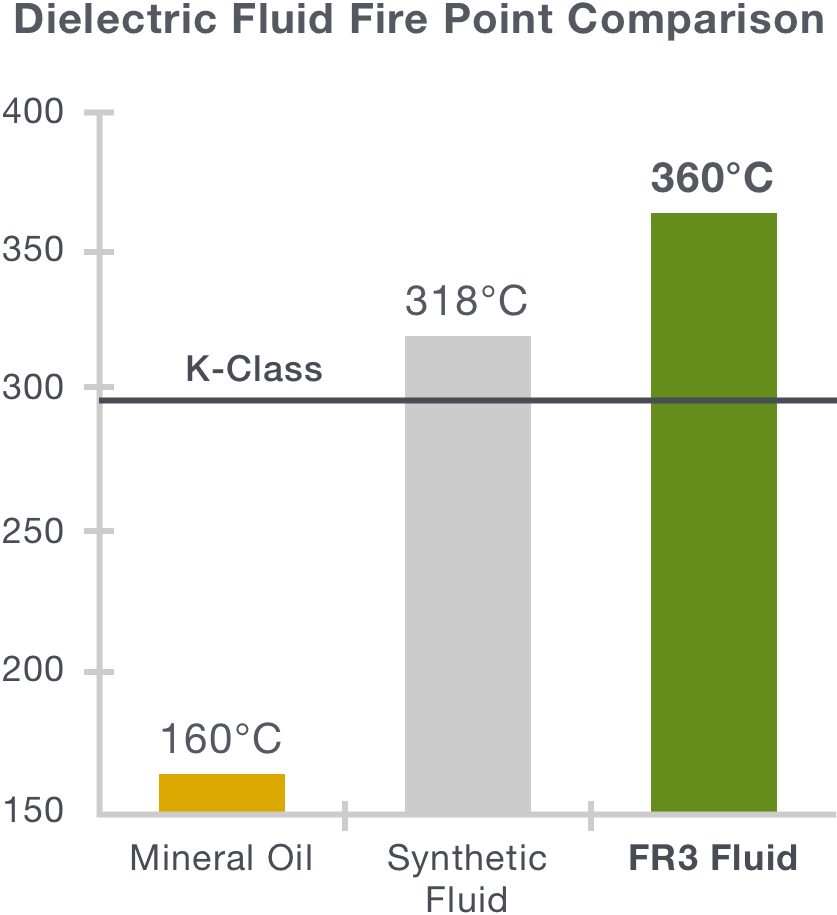

The best dielectric fluid gets you improved cost in use, reliability, performance, fire safety, and environmental impact.

The natural ester fluid that beats the alternatives

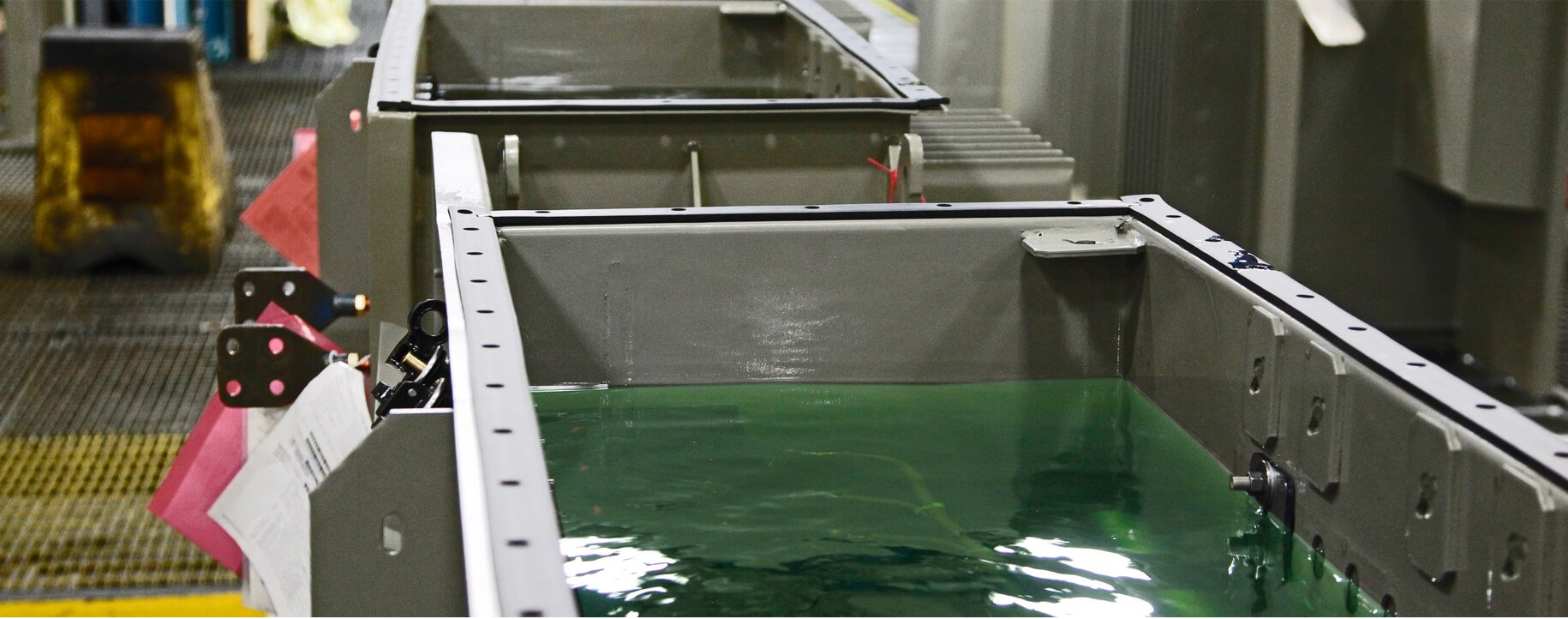

Derived from 100% renewable vegetable oils, biobased FR3 fluid is superior to mineral oil and other natural ester fluids for use in distribution and power generation transformers of all voltage classes (both new and retrofilled); HV testing validates use of FR3 fluid though 765kV. FR3 fluid is also suited for other fluid-filled distribution and power equipment, such as voltage regulators, circuit breakers (switchgear), rectifiers, phase-shifters, and HVDC transformers.

Its unique properties provide advantages that mineral oil cannot match, and its effectiveness has been proven for decades in millions of transformers across the globe. In particular, with FR3 fluid you can expect:

Significantly improved fire safety, with no reported incidents in 20+ years of use

Extended asset and insulation life, for cost savings during an asset’s life

Enhanced load capacity

Improved environmental benefits

FR3 fluid exceeds IEEE and IEC specifications, and is FM approved and UL listed.

FR3 fluid's properties make it superior to mineral oil. Contact us to find out how FR3 fluid can meet your business's and community's needs, or find FR3 fluid.

FR3 fluid properties: Standard acceptance values and typical values

| Standard test methods | ASTM D6871/IEEE C57.147 | IEC 62770 | FR3 Fluid | ||

|---|---|---|---|---|---|

| Property | ASTM | ISO/IEC | As-received new fluid property requirements | Unused new fluid property requirements | Typical |

| Physical | |||||

| Color | D1500 | ISO 2211 | ≤1.0 | - | 0.5 |

| Flash Point PMCC (ºC) | D93 | ISO 2719 | - | ≥250 | 260 |

| Flash Point COC (ºC) | D92 | ISO 2592 | ≥275 | - | 320-330 |

| Fire Point (ºC) | D92 | ISO 2592 | ≥300 | >300 | 350-360 |

| Pour Point (ºC) | D97 | ISO 3016 | <-10 | ≤-10 | -21 |

| Density at 20ºC (g/cm3) | - | ISO 3675 | - | ≤1.0 | 0.92 |

| Relative Density (Specific Gravity) 15ºC | D1298 | - | ≤0.96 | - | 0.92 |

| Viscosity (mm2/sec) | D445 | ISO 3104 | |||

|

100ºC |

≤15 | ≤15 | 7.7 - 8.3 | ||

| 40ºC | ≤50 | ≤50 | 32 - 34 | ||

| 0ºC | ≤500 | - | 190 | ||

| Visual Examination | D1524 | IEC 62770 4.2.1 | Bright and clear | clear, free from sediment and suspended matter | clear, light green |

| Biodegradation | OECD 301 | readily biodegradable | readily biodegradable | readily biodegradable | |

| Electrical | |||||

| Dielectric Breakdown (kV) | D877 | - | ≥30 | - | 47 |

| Dielectric Breakdown (kV) | |||||

| 2mm gap | D1816 | - | ≥35 | - | 60-70 |

| 2.5mm gap | - | IEC 60156 | - | ≥35 | 70-80 |

| Dielectric breakdown / impulse, needle/spere, 25C, 25.4mm[kV] | |||||

| Gassing tendency (mm/min) | D2300 | - | ≤0 | - | -79 |

| Dissipation Factor | |||||

| 25ºC (%) | D924 | - | ≤0.20 | - | 0.010 - 0.15 |

| 90ºC (tan ∂) | - | IEC 60247 | - | ≤0.05 | 0.02 |

| 100ºC(%) | D924 | - | ≤4.0 | - | 0.41 - 3.85 |

| Chemical | |||||

| Corrosive Sulfur | D1275 | IEC 62697 | non-corrosive | non-corrosive | non-corrosive |

| Water Content (mg/kg) | D1533 | IEC 60814 | ≤200 | ≤200 | 4 - 50 |

| Acid Number (mg KOH/g) | D974 | IEC 62021.3 | ≤0.06 | ≤006 | 0.013 - 0.042 |

| PCB Content (mg/kg) | D4059 | IEC 61619 | not detectable | free from PCBs | not detectable |

| Total Additives | - | IEC 60666 | Max weight fraction 5% | <2% | |

| Oxidation Stability (48 hrs, 120ºC) | - | IEC 61125C | |||

| Total Acidity (mg KOH/g) | - | IEC 62621.3 | ≤0.6 | 0.1 | |

| Total Acidity (mg KOH/g) | - | ISO3104 | ≤30% increase over initial | 17.1%% increase | |

| Dissipation Factor at 90ºC (tan ∂) | - | IEC 60247 | ≤0.05 | 0.1 | |

Note: Specifications should be written referencing only the defined ASTM or IEC acceptance values and test methods. The listed “typical” values are averaged values summarized from a significant number of data points over many years; they are not to be identified as acceptance values.

ASTM D6871 Standard Specification for Natural (Vegetable Oil) Ester Fluids Used in Electrical Apparatus.

IEC 62770: Fluids for electrochemical applications — Unused natural ester liquids for transformers and similar electrical equipment.

A transformer filled with FR3 fluid complies with the transformer temperature operating ranges requirements defined in IEEE C57.12.00 and IEC 60076-1.

Learn how FR3 fluid’s properties make it superior to mineral oil. Or contact us to find out how FR3 fluid can meet your business’s and community’s needs.

FR3 natural ester fluid details: Delivering superior results

Formulated for high-temperature performance

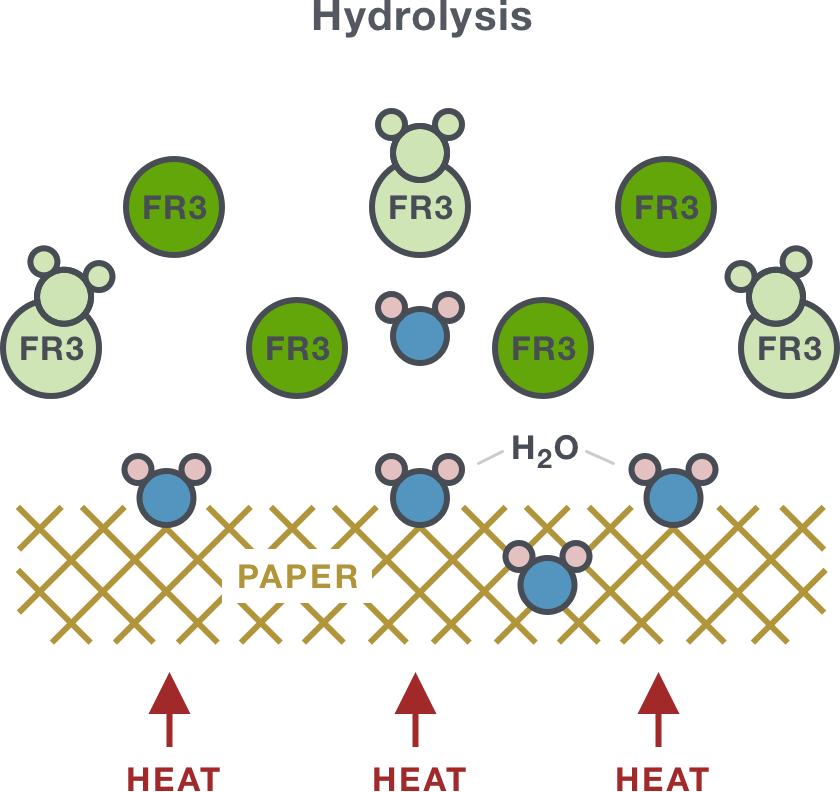

A transformer’s solid insulation system plays a critical role in its possible failure and in its temperature-related operating limits. The thermal class of the insulating materials constrain the transformer’s (temperature) operating limits. (The typical reference point is the average winding rise (AWR) of the transformer, which is limited to 55°C for mineral-oil designs with standard Kraft paper and 65°C for mineral-oil designed with thermally upgraded Kraft (TUK) paper for an average ambient temperature of 30°C. Put another way, historical standards were written to accommodate a thermal class of 105 for mineral-oil designs with standard Kraft paper and 120 mineral-oil designs with thermally upgraded Kraft (TUK or TUP) paper.)

As validated by standard accelerated testing method, a transformer with TUK paper and filled with FR3 natural ester fluid can operate 15°C to 20°C warmer, holding a thermal class of 140 without reducing reliability and while maintaining the same life expectancy.2

This allows for an increased load capacity for both distribution and power transformers filled with FR3 fluid, due to the possible increasing temperature rise limits. Explore the high-temperature capability of FR3 fluid compared to mineral oil.

Learn more about how FR3 fluid’s thermal capacity can provide more load capacity and resilience to your grid than mineral oil, and see how this attribute of FR3 fluid contributes to total cost of ownership.

Explore your options

FR3 fluid brings unmatched advantages. Contact us to consult with one of our experienced dielectric experts to learn how.

FR3® Dielectric Fluid Brochure

Get an overview of FR3 natural ester dielectric fluid.

FR3® Dielectric Fluid Data Sheet

Get technical details about FR3 fluid, including functional specifications.

FR3® Fluid Storage and Handling Guide

Get FR3 fluid storage and handling guidelines to help assure quality and safety.

Retrofilll Guide for Distribution Transformers

Get our guide for atmospheric retrofilling of 25kV (or lower) distribution class transformers ≤7500kVA with FR3 fluid.

Retrofill Guide for Power Class Transformers

Get our guide for retrofilling power class transformers >7500kVA with FR3 fluid.

FR3® Fluid Loading Guide

Get test-result specifications for the “A” and “B” factors for thermally upgraded Kraft paper in FR3 fluid.

FR3® Fluid Behavior in Cold-Temperature Environments

Get reference data and test results in our white paper detailing FR3 fluid’s reliable performance in cold temperatures.

FR3® Fluid Cold Start Recommendations

Get reference data and recommendations in our white paper about cold start procedures for transformers filled with FR3 fluid.

Transformer Power Factor and FR3® Fluid

Get reference data and a description of why the power factors of transformers filled with FR3 fluid are usually higher than similar mineral-oil-filled transformers.

1. Based on accelerated aging tests with Kraft and thermally upgraded Kraft (TUK) paper, per IEEE C57.100.

2. IEC 60076-14 Part 14: Liquid-immersed power transformers using high-temperature insulation materials. Edition 1.0. September 2013; IEEE C57.154 Standard for the Design, Testing, and Application of Liquid-Immersed Distribution, Power, and Regulating Transformers Using High-Temperature Insulation Systems and Operating Elevated Temperature. October 30, 2012.

The products and services described on this website may not be available in all jurisdictions or to all persons.

Superior moisture tolerance

Superior moisture tolerance Exceptionally high flash and fire points

Exceptionally high flash and fire points