Product Solutions

Corrugated boards are produced in the corrugator. This is a set of machines that runs in parallel in a continuous process to combine together three, five or seven sheets of paper to respectively produce single-, double- or triple- wall board. In the corrugator, through different sets of rolls moving at high speed and subject to various temperature and moisture conditions, the layers of the corrugating medium are fluted and glued to the linerboard to produce the corrugated boards.

The glue used in the production of corrugated boards is a critical element. Selection of the appropriate adhesive will ensure that the quality of the board is preserved throughout production, distribution and consumer use. From a production perspective, the glue quality can significantly affect line efficiency and production performance.

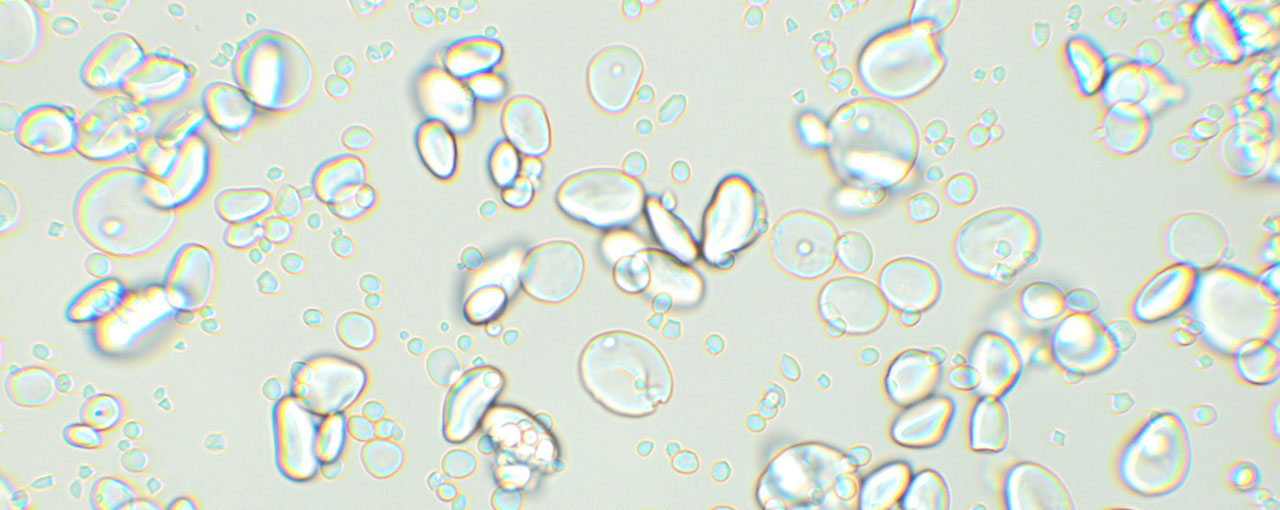

Starch is a nature-derived water-based adhesive and is one of the preferred raw materials for glue formulation in corrugated board production. This is due to its technical properties and environmental profile. Starch granules suspended in cold water don’t have adhesive properties and need to be broken down in warm water with sodium hydroxide to form a viscous liquid with glue properties.

C☆Gum™ are our traditional native starch solutions based on corn and wheat.

C☆iGum™

C☆iGum™ grades are our advanced starch-solutions for glue formulation. They are wheat and corn-based modified starches with improved rheology and gluing performance properties designed for high-efficiency corrugated board production.

The products and services described on this website may not be available in all jurisdictions or to all persons.