Polyester

Here are a few of Cargill’s polyester products and how they can affect the end products that they are added to.

Pripol™ dimer diol is bio-based*. This product’s high purity grade improves flexibility, mechanical proprieties and offers hydrolytic and thermos-oxidative stability.

Priplast™ polyester polyols offer unique proprieties to copolyesters (COPE) elastomers. They range from soft to semi-rigid products offering good thermo-oxidative stability and hydrolysis resistance and outperform conventional polyols.

Priplast™ polyester polyols can help increase water resistance, widen the window of application temperature, enhance melt flow and reduce the carbon footprint by replacing other, traditionally non bio-based products.

These elastomers are high-end block copolymers and find use in heavy-duty sports, automotive, electronic cabling and tubing applications.

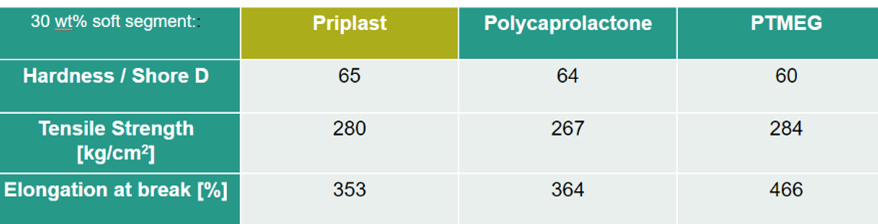

Properties of Priplast™ COPE vs. Industry standards PTMEG or Polycaprolactone

Compared to industry standard PTMEG or Polycaprolactone chemicals, Priplast™ COPE polyester polyols provide mechanical property advantages, petrol resistance (much higher than PTMEG standard) and excellent aging performance in regard to UV and hydrolytic stability.

*ASTM D6866

Performance polyesters

Priplast™ 3238

Priplast™ 3238 is an amorphous polyester polyol (MW 2000) for bio-based polyurethane systems. This liquid and versatile building block is for use in polyurethane systems such as adhesives, polyurethane dispersions, sealants and elastomers.

Priplast™ 3238 polyol provides extreme hydrophobicity, excellent color and enhanced durability. It also brings good wetting properties, adhesion to various substrates, including low polarity plastics, and prevents cracking. Priplast™ 3238 polyol is an ISCC PLUS certified product. The vegetable oil-based content comes from ISCC certified sources.

Pripol™ 2033

As a low viscous curing agent, Pripol™ 2033 offers enhanced properties to your polyurethane and polyester coatings, adhesives and elastomers.

By enhancing flexibility, cracks are reduced, and impact resistance increased. This fully amorphous dimer diol also offers excellent moisture barrier protection and chemical resistance.

Pripol™ 2033 is an ISCC PLUS certified product. The vegetable oil-based content comes from ISCC certified sources (mass balance).