Compressors

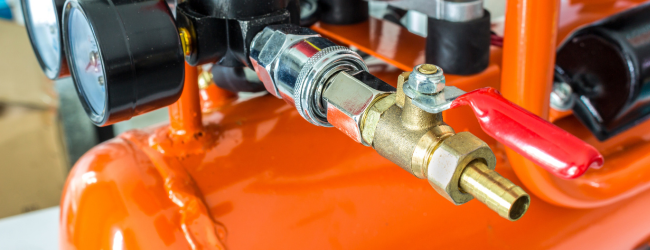

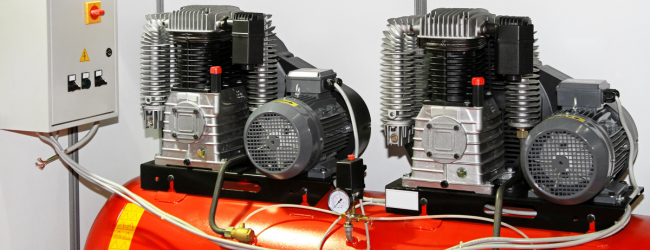

Lubrication is vital for efficient compressor operation and the correct use of high-quality lubricants can substantially extend compressor life, providing maintenance and production savings in the longer term.

Esters & compressor fluids

We provide a broad range of both synthetic ester base oils (Priolube™) and polyalkylene glycols (Emkarox™) for use in compressor formulations. Both technologies play a critical role in sealing, preventing corrosion and wear, and protecting internal metal parts. Our ester ingredients provide a multitude of benefits to both the formulator and the end user. These are highlighted in the table below:

| Ester feature | Formulation benefit | End user benefit |

|---|---|---|

| Provides excellent lubricity | Reduces valve deposits | Extends equipment life |

| Protects against wear | Extends drain intervals/reduces consumption | Ensures safer operational use at high temperatures |

| Delivers low coefficient of friction | Increases energy efficiency (up to 10%) | Reduces maintenance costs and downtime |

| Improves thermal stability | Improves operating temperature range | Improves safety performance |

Discover products for compressor oils

Priolube™ 1939

A highly oxidatively stable, low volatility, hydrolytically stable ester providing enhanced lubrication performance.

Priolube™ 1941

A highly oxidatively stable ester that provides enhanced lubrication, particularly for high temperature applications.

Priolube™ 1973

Priolube™ 1973 is an ISO 46, oxidatively stable and hydrolytically stable ester, suitable for use in a wide range of automotive and industrial applications.

Priolube™ 1889

A high-performance and highly viscous, thermal and oxidatively stable ester that is suitable for use as a base fluid in high temperatures.

Priolube™ 2500

A synthetic lubricant base fluid that is suitable for use in a wide range of applications. It is European Ecolabel compliant and is featured on the LuSC list.

Priolube™ 3970

A low viscosity, oxidatively stable, low deposit forming polyol ester. It is a high performing lubricant with excellent oxidative stability.