Polymer Additives Effects

Cargill is a leading global supplier of specialty additives for the plastics industry, working with our customers to meet market demands and consumer needs. Supported by scientific testing, Cargill’s diverse range brings functionality and innovation together to deliver additives that offer differentiated solutions.

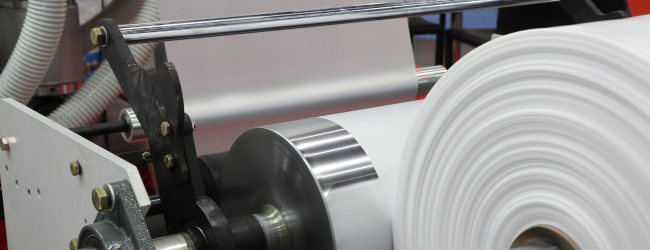

Cargill offers a wide range of additives that are added during the processing of plastic and polymers to bring added benefits to the process or the final product. These additives are useful for a variety of processing techniques and applications such as automotive applications, caps and closures, film structures, extrusion, resin productions, foamed polymers, injection molding, liner compounds and plastisols.

Anti-block

The Cargill range of anti-blocking additives offer an effective and sustainable way to reducing the problem of blocking in polymer films. Added at low addition levels they provide optimized blocking performance without impacting the clarity of the film.

Anti-fog

The Cargill range of anti-fogging additives for plastics allows water to spread into a continuous and uniform transparent layer of water on the surface of films. This results in improved light transmission and transparency which has benefits in both agricultural and food packaging applications.

Anti-scratch

Anti-scratch additives are proving ever-more popular due to the increasing need for more durable and re-usable plastics. Anti-scratch additives reduce the visibility of scratches and scuffs on the surface, resulting in an improved look and an increased lifetime of the part.

Mold release

The Cargill range of mold release additives offer an effective solution in a range of polymer types and applications. These bio-based additives improve the quality of molded parts, and help to release parts from the mold more easily resulting in a more efficient process and less waste.

Anti-static

Anti-static agents are added to polymers to provide static protection by lowering the resistivity of the material. Cargill’s anti-static product range offers migrating and permanent solutions in a range of physical forms and longevity to provide the required static control for different materials and applications.

The Ionphase™ range of Inherently Dissipative Polymers (IDP), also known as permanent anti-stats or ion conductive polymers, reduce the resistivity of the polymer providing control and safety for static related issues.

Cargill’s Atmer™ anti-static additives are used in applications where static protection is needed such as food and beverage and cosmetics packaging to prevent dust attraction that can affect the performance or appearance of the parts.

Plasticization

Plasticization additives include both monomeric and polymeric plasticizers that work to increase the plasticity or fluidity of a polymer. Plasticizers are particularly useful in PVC, but can be used in other polymers such as synthetic rubbers, synthetic rubber derivatives, and other polar polymers such as polystyrene and ABS.

Reactor anti-fouling

Polymer additives help to increase the stability of end products and provide additives that support characteristics that prevent fouling.

Slip

Slip additives are products which can be added to polymers to control friction. They are added directly into the polymer during the extrusion process and migrate to the surface as the polymer cools, allowing a solid lubricating layer to form.

Torque release

Our torque release additives reduce friction in plastic caps and closures to allow easier application and removal of the part. These bio-based, high stability additives ensure more efficient processing in a range of packaging applications. Our additives are recommended for use at very low addition levels and are recommended to be dosed via a masterbatch or compound.