Anti-scratch

Anti-scratch additives are proving ever-more popular due to the increasing need for more durable and re-usable plastics. Anti-scratch additives reduce the visibility of scratches and scuffs on the surface, resulting in an improved look and an increased lifetime of the part.

In particular, car manufacturers are looking to increase the lifetime of the plastic parts and using scratch and scuff resistant materials is one way to achieve this. Anti-scratch additives can also be utilized in household appliances, cosmetic packaging, and high-end electronic devices.

Our range of anti-scratch additives is proven to reduce scratch visibility and whitening while maintaining high stability and low visible bloom over time and after exposure to heat and UV light. They migrate to the surface by controlled migration through the polymer and work by reducing friction at the surface.

Some key benefits associated with this product range include reduced scratch width, reduced scratch whitening, improved scratch smoothness, low visible bloom, increased oxidative stability, low odor, and improved mold release to name a few.

Recommended products and addition levels will vary depending on exact polymer, formulation and application. Our technical experts are happy to work on customer projects to find the best solution for you.

Anti-scratch in Polyolefins

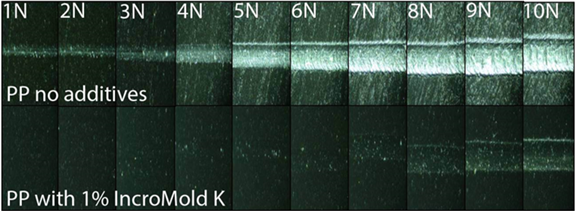

Our range of anti-scratch additives reduce the visibility of scratches and scuffs in polyolefins by reducing the whiteness of the scratch. This is particularly important on colored or black plastic parts such as automotive trim, high-end cosmetic packaging and household appliances.

In particular, IncroMold™ K is excellent at reducing the scratch whiteness when added at levels around 0.5 - 1%.

Anti-scratch in Engineering Polymers

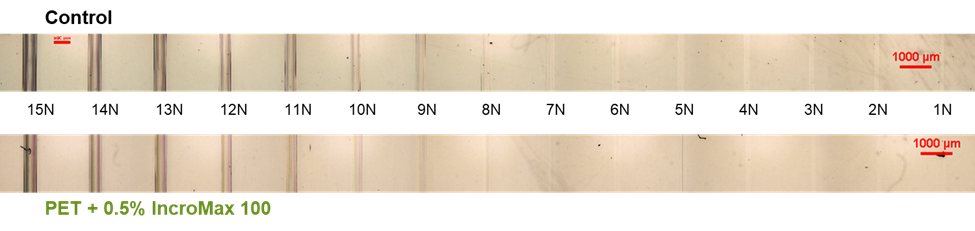

There are applications using polymers such as PET, PLA, PC and PMMA where maintaining clarity is just as important as anti-scratch performance.

Our IncroMax™ range of anti-scratch additives offer solutions for these polymers that do not impact clarity and haze of the final part.

IncroMold™ K

IncroMold™ K is an internal molding release and anti-scratch additive used to improve cycle time, productivity and surface finish in a variety of polymers, suitable for use at high temperatures (>280 °C).

Anti-scratch additives to increase scratch and scuff resistance in plastics

IncroMax™ 100

IncroMax™ 100 is a unique additive for a range of Polyesters including PET, PLA and PBT, and reduces friction on the polymer surface at very low addition levels.

This leads to a range of product and efficiency improvements, such as improved packing and de-nesting, reduced scuff and scratch, and a reduction in mold release force.

Incroslip™ SL

Incroslip™ SL is a specially developed additive with exceptional slip, anti-scratch and stability properties.

It is patented market leading technology that delivers long-lasting high-slip along with superior color, oxidative stability and improved organoleptic properties.

IncroMax™ 300

Designed especially for polycarbonate, IncroMax™ 300 is a friction reduction additive for easier processing and improved scratch resistance in sheet and glazing applications.

IncroMax™ 300 provides essential reduction to surface friction as an internal lubricant as well as improving mold release properties.