Lubricant Applications

Our extensive portfolio of products allows the formulator to create high performoing, premium lubricant formulations across a wide range of application areas with an unrivalled degree of formulation flexibility.

We recognize the importance of sustainability while still meeting the required performance levels, therefore many of our products are derived from renewable raw materials and are on the EU Ecolabel Lubricant Substance Classification (LuSC) list.

Chain oils

We supply base oils which are used in chain oil formulations for a wide range of applications, including high temperature and food grade chain oils. Our base oils aid lubrication of chains to allow the free movement of components and to prevent excessive wear.

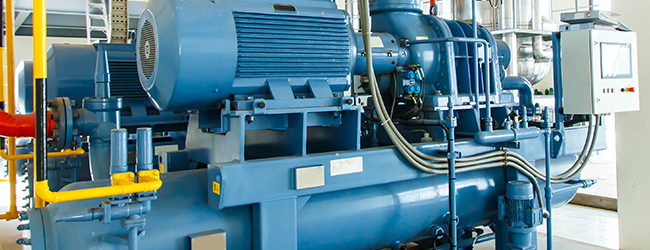

Compressors

Lubrication is vital for efficient compressor operation and the correct use of high-quality lubricants can substantially extend compressor life, providing maintenance and production savings in the longer term.

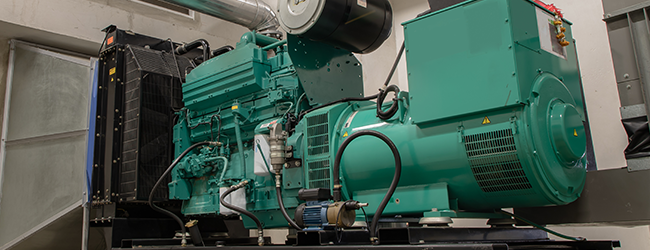

Engine oils

We create, make and sell engine oil base oils and additives tailored to specific customer needs.

Driven by evolving legislation, increasingly tough original equipment manufacturer (OEM) approvals and an uncertain energy transition, the engine oil formulator must continue to innovate and adapt. Having worked with formulators for decades, we can help you overcome emerging challenges by developing new products and chemistry for you to achieve your goals.

Through many years of working in the automotive industry, our team of technical specialists have the relevant experience necessary to offer advice in respect of product selection and treat rates to help deliver optimum engine oil performance for traditional transportation, and electrified transport.

Environmentally acceptable lubricants

We create, make and sell synthetic lubricant base oils that are sourced from renewable raw materials for environmentally sensitive areas where oil release or spillage may occur.

Driveline and transmission for I.C.E.

The introduction of new and more sophisticated transmission systems are placing greater demands on the fluids that lubricate them. Original equipment manufacturers (OEMs) are demanding fluids which have specific frictional characteristics; drain intervals are getting longer and in some cases "fill-for-life" fluids are required. Additionally, new clutch materials are also being developed and it cannot be assumed that additives which work well with one type of clutch material will work well with new materials.

We have been a supplier of ingredients for transmission fluids and driveline applications for many years. We have excellent application expertise as well as knowledge of the changing regulations and requirements, and we can help you overcome the technical challenges you might face when formulating fluids for driveline and transmission applications.

Driveline and transmission for E.V.

While EVs do not have gearboxes in the traditional sense, a transmission is still required to move torque from the motor to the wheels. EV transmissions have specific operating conditions, including faster rotational speeds, much higher torque loads and the presence of electrical fields and high voltages. This means that EVs require specialist fluids and a good understanding of the challenges involved in formulating high performance lubricants. Additionally, manufacturers are seeking ways to improve efficiency as well as reduce the number of fluids required in an EV by sharing fluids amongst the motor, transmission and power electronics.

We offer dielectric base oils and additives specifically developed for high efficiency EV applications.

Food grade

Food grade lubricants are used during the processing, production, manufacture and packaging of food products. Lubricating equipment used in the food processing industry presents a unique challenge. The lubricant must first provide the basic desired technical performance, but secondly must comply with acceptable industry standards on the use of approved base fluids and additives.

Lubricant formulators are limited in the types and amounts of additives that can be used. Today the National Sanitation Foundation (NSF) manages a lubricant evaluation program where base oils and additives can be certified and approved for use in formulations where food contact is a consideration. NSF registered products are listed in the 'White Book' for food grade lubriants.

Gas turbine lubricants

Our Priolube™ esters provide a multitude of benefits to formulators of gas turbine engine lubricants. Gas turbine technology continues to evolve with a desire for increased levels of production efficiency, and of course, business critical cost savings. The primary challenge in gas turbine lubrication remains unchanged, maintaining performance while being exposed to high temperatures.

We have developed a superior range of Priolube™ branded products that possess the performance capability to cope with the high temperature aspect of this challenging application.

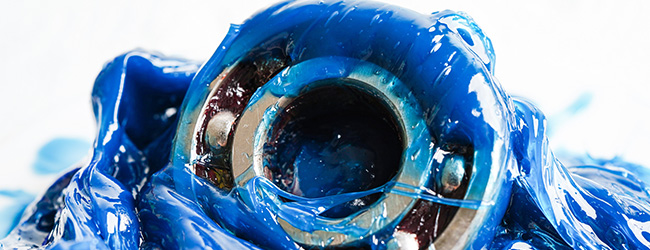

Greases

Lubricating greases can be defined as solid to semi-solid materials which represent dispersions of a thickening agent in a liquid lubricant. We are a major global supplier of high-performance synthetic ester and polyalkylene glycol base oils, viscosifiers and soap production additives into grease applications.

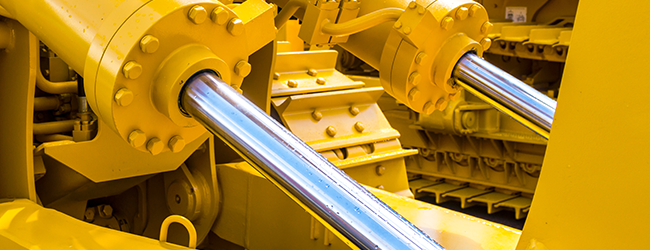

Hydraulic fluids

Hydraulic fluids play a pivotal role in the smooth operation of a well-balanced and well-designed hydraulic system. Their primary function is to convey power; however a hydraulic fluid can also be vital for efficient heat transfer, lubrication and corrosion prevention.We have developed an industry-leading range of base fluids which provide outstanding performance benefits to hydraulic fluid formulations.

Marine stern tube

We are world leading in the development of synthetic base oils for use in environments where oil release or spillage may occur and have developed an industry leading range of Priolube™ ester base oils. Many of our products designed for environmentally sensitive areas and almost all have low toxicity towards aquatic organisms.Our products are also European Ecolabel certified (on the LuSC list), suitable for formulation under Vessel General Permit (VGP) and most are USDA Biopreferred®.

Metalworking and forming

The metalworking industry is constantly undergoing change, driven by the demand for superior performance products to provide improved productivity at lower cost and by legislation. As technologies and working practices develop; metalworking fluid formulators, as well as base fluid and additive suppliers must adapt quickly to support the advances taking place.

We can help you meet the challenging requirements placed on your fluids. We supply ingredients suitable for use in all types of formulations across most metalworking and forming applications.