C☆iSize™

C☆iSize™ low cationic starches are designed to help improve paper surface strength, reduce effluent loads, and help to minimize stock losses. C☆iSize™ allows to replace expensive cellulose fiber by filler without necessarily sacrificing quality. Low cationic starches demonstrate great ink-jet printability, making them an ideal choice for modern office environments and digital printing applications.

In addition, their higher presence in the broke leads to improved drainage, reduced refining energy requirements, increased production capacity, and potential savings in retention aids, sizing agents, and dry strength agents.

Benefits

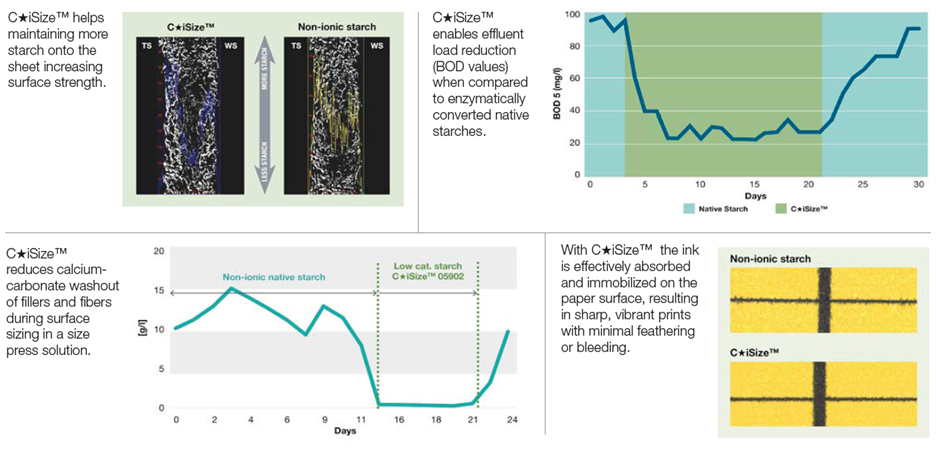

- Reduction of effluent load: from our trials is evident that the Chemical Oxygen Demand (COD) and the Biochemical Oxygen Demand (BOD) values of a filtrate from repulped, surface-sized paper, decrease with the add-on of C☆iSize™ low cationic starches.

- Improved self-retention: low cationic starch tends to achieve a self-retention rate of 90% (vs 30% retention rate of native starches) when paper is manufactured from 100% surface sized broke.

- Improved machine runnability: the enhanced binding power of low cationic starches contributes to improved machine runnability, allowing for higher molecular weights without compromising machine performance.

- Replacement of fiber with filler: C☆iSize™ low cationic starches support filler retention, leading to an increase in filler levels. By reducing the dosage of fresh filler (a 5% reduction has been achieved in our trials), C☆iSize™ enables significant material annual savings.

- High surface strength: at comparable viscosity level, C☆iSize™ low cationic starches tend to less sheet penetration when applied with a size or film press compared to a non-ionic native starch enabling a 30% reduction of surface sizing starch consumption.

- Ink-Jet printability: the enhanced print quality achieved with low cationic starches allows for precise and accurate reproduction of text, images, and graphics with high colour gamut, meeting ambitious standards of ink-jet printing

Product Range

| TECHNICAL INFORMATION | ||

|---|---|---|

| Product Range | Raw Material | Key Characteristics |

|

C☆iSize™ 25869 |

Wheat | No viscosity adjustment needs |

| C☆iSize™ 25874 | Wheat | Very good temperature stability |

| C☆iSize™ 25903 | Wheat | Also suitable as spray starch |

| C☆iSize™ 05902 | Corn | pH adjusted for optimal enzymatic conversion |

Technical Highlights

Regulatory Status

| Product Range | Nordic Ecolabelling - Paper Products - Chemical Module v 3.0 | BfR XXXVI Paper and board for food contact | BfR XXXVI/2 Paper and board for baking applications | FDA 21 CFR § 178.3520 | GB9685:2016 * |

|---|---|---|---|---|---|

|

C☆iSize™ 25869 |

X | X | X | X | X |

| C☆iSize™ 25874 | X | X | X | X | X |

| C☆iSize™ 25903 | X | X | X | X | X** |

| C☆iSize™ 05902 | X | X | X | X | X** |

*Chinese National Food Safety Standard for Uses of Additives in Food Contact Materials and Their Products. According to GB 9685:2016 the product can be used with no limitations in paper and cardboard intended for food contact.

**Max. dosage 1 % during manufacturing of paper and board intended for food contact

Applications

The Cargill Advantage

To support customer corporate sustainability commitments, Cargill can offer solutions produced from sustainably sourced raw materials that are benchmarked at Silver Level according to the Farm Sustainability Assessment (FSA).1

1. FSA is a standardized reference developed by SAI Platform, a food industry organization dedicated to advancing sustainable agriculture in the food chain. It’s designed to help producers assess their sustainable practices and support manufacturers in sourcing sustainably grown products.