Coating Starches

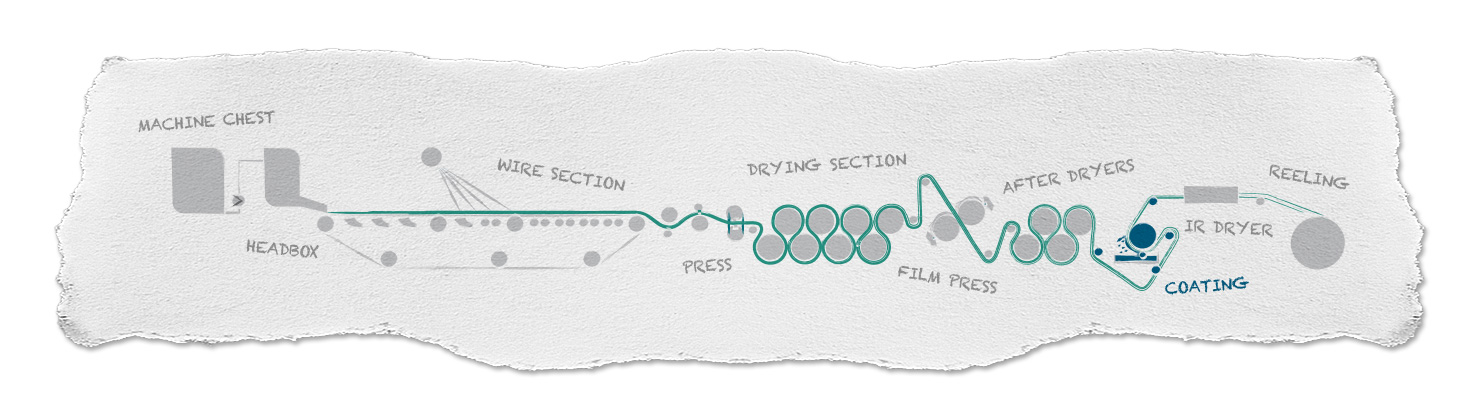

Paper coating is performed either in the paper machine after the drier section (on-line coater) or in a separate machine (off-line coater). Coating is applied on the sheet surface as a concentrated dispersion of pigments, binders and additives. Coating can be applied with different systems, with the most common one being a metered size press (MSP), a blade coater and most recently the use of a curtain coating system. Coating can be applied at a very high speed of up to 1,800m/min (108km/h paper web speed). Therefore, coating color rheology is a central element to ensure good coated paper quality.

Starch is an important coating binder. It is essential to improve coating color rheology on the one hand, and final paper quality enhancing optical properties like brightness, gloss or opacity, sheet smoothness and most importantly printability and print image quality, on the other. Starch can also replace latex in the coating composition and, therefore, meet the need for more bio-based raw materials.

Our solutions

Our portfolio ranges all the way from our C☆Flex™ and C☆Size™ native starches, to our C☆Film™ traditional modified starches and C☆iFilm™ engineered starch solutions, and to more advanced technologies like cold soluble polymers C☆iCoat™.

The products and services described on this website may not be available in all jurisdictions or to all persons.